Welcome to Foodsure!

Tomato Ketchup Recipe Formulation

300000 INR/Unit

Product Details:

X

Tomato Ketchup Recipe Formulation Price And Quantity

- 300000 INR/Unit

- 01 Unit

Tomato Ketchup Recipe Formulation Trade Information

- New Delhi

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Pet Bottle Packaging

- All India

- ISO9001:2015

Product Description

Tomato Ketchup Recipe Formulation

Creating a Tomato Ketchup Recipe Formulation as part of Foodsure research & development (R&D) process required a method to create products that met standards for quality ,aste & safety . Below are general guidelines for the development process for creating a mayonnaise recipe: For the creation of ketchup , this includes elements such as flavor profile , texture , frozen consistency , & more . & food restrictions .

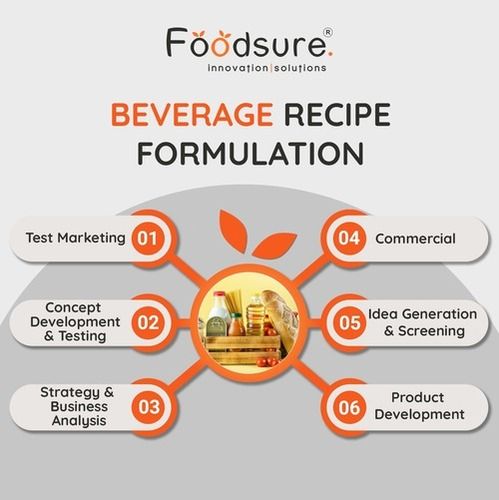

- Market Research : Examine current market trends , customer preferences & competitor products to identify common trends or innovation opportunities .

- Ingredient Selection : Choose the right ingredients according to Foodsure standards & the desired properties of your mayonnaise . Think about things like oil , egg yolks , & other spices .

- Use recipes : Create tomato recipes based on selected ingredients .

- Laboratory Testing : Small tests are carried out in the laboratory to evaluate the hearing characteristics , safety & all the advantages of the initial design .

- Improve & iterate : Make appropriate changes to the map based on test results . Improve the recipe again & again until you get the product you want .

- Scale-up : Once a useful model is found , production is scaled up so that the model can be tested under near-everything conditions .

- Pilot Plant Trial : Testing the Scalability , Efficiency & Consistency of the Mayonnaise Process The trial was carried out in the pilot plant .

- Sensory Evaluation : Create a sensory panel to evaluate the product's taste , aroma , texture & overall user appeal .

- Quality Assurance & Testing : Strict safety measures , including microbiological testing , are used to ensure the safety & stability of mayonnaise .

- Information : Write a final report including evaluation criteria & methodology . This information is necessary for the consistency of the production process .

- Regulatory Compliance : Make sure the ketchup recipe complies with all laws & safety standards .

- Production : Changes to all production guidelines , including any necessary changes identified during the development process .

- Selection & Marketing : Develop marketing strategies to introduce new ketchup products to the market . Consider packaging , product & location

All methods & collaborations with food scientists, chefs & other experts are very beneficial in terms of food quality . Additionally , keeping sustainability , nutrition considerations & consumer preferences in mind can help the product succeed in the marketplace .

Process flow chart for making tomato ketchup:

- Raw Material Reception: Fresh tomatoes are received and inspected for quality.

- Cleaning and Sorting: The tomatoes are thoroughly cleaned to remove dirt and debris. They are then sorted to remove any damaged or spoiled tomatoes.

- Chopping and Crushing: The cleaned tomatoes are chopped into smaller pieces and then crushed to form a pulp.

- Heating: The tomato pulp is heated to a specific temperature to facilitate the extraction of juice and to kill any harmful bacteria present.

- Straining: The heated tomato pulp is strained to remove seeds, skin, and any remaining solids, resulting in a smooth tomato puree.

- Mixing: The tomato puree is mixed with other ingredients such as sugar, vinegar, salt, and spices to achieve the desired flavor profile.

- Cooking: The mixture is cooked at high temperatures to thicken the ketchup and develop its characteristic flavor.

- Cooling: The cooked ketchup is cooled down rapidly to prevent spoilage and maintain freshness.

- Packaging: The cooled ketchup is filled into bottles or containers, sealed, and labeled.

- Quality Control: Samples of the finished product are tested for quality, including taste, texture, color, and shelf life.

- Storage: The packaged ketchup is stored in a controlled environment to maintain its quality until it is ready to be shipped to retailers or distributors.

- Distribution: The finished tomato ketchup is distributed to supermarkets, grocery stores, restaurants, and other food service establishments for sale to consumers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Food Recipe Formulations' category

Back to top