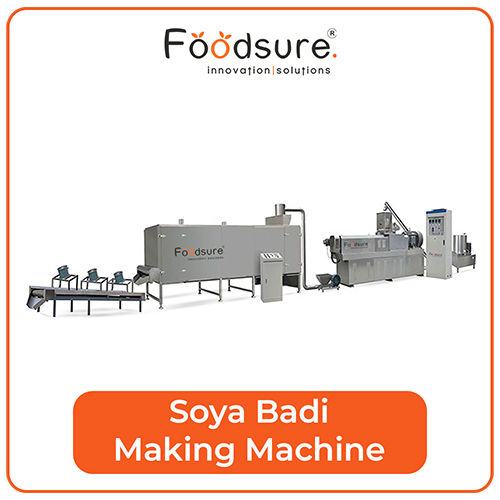

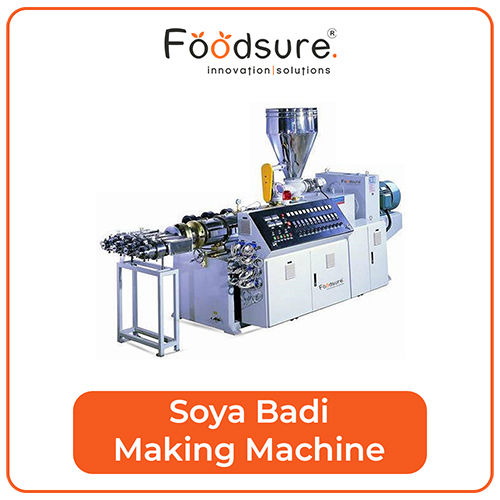

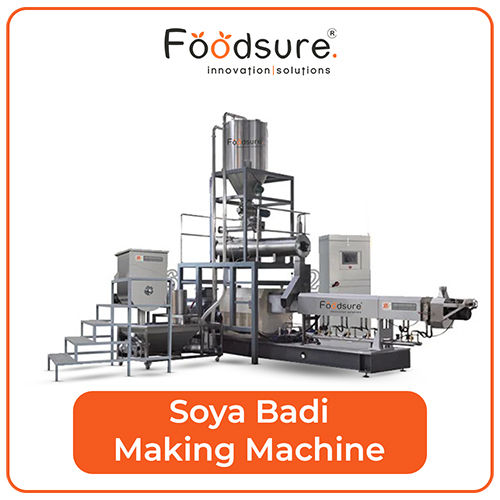

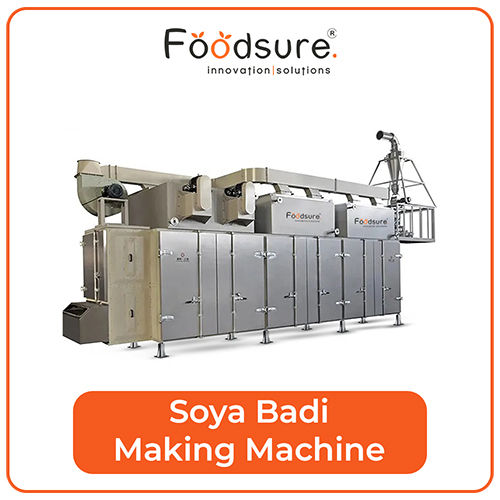

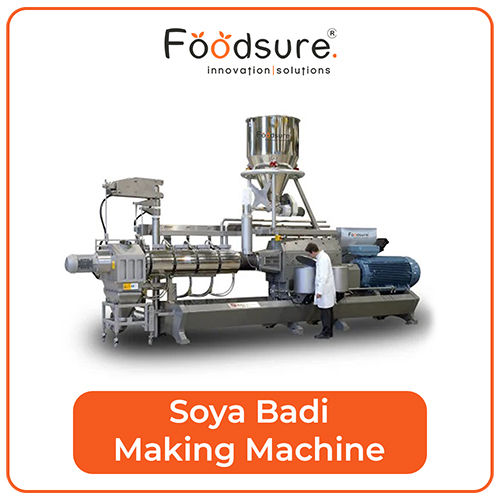

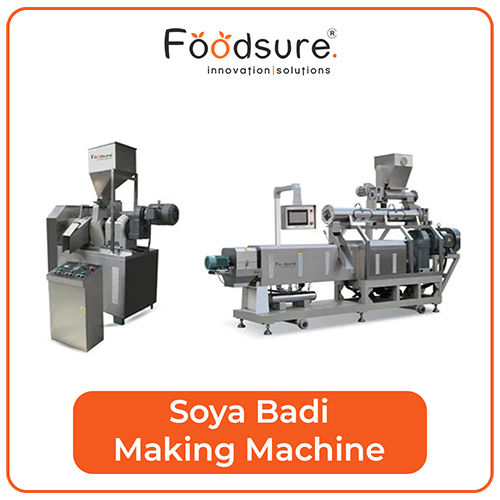

Soya Badi Making Machine

Product Details:

- Product Type Soya Chunks Making Machine

- General Use Soya Chunks Making

- Material Stainless Steel

- Type Food Processors

- Capacity 500 Kg/hr

- Weight (kg) 1500 Kilograms (kg)

- Product Shape Ring

- Click to View more

Soya Badi Making Machine Price And Quantity

- 2500000.0 INR/Piece

- 1 Piece

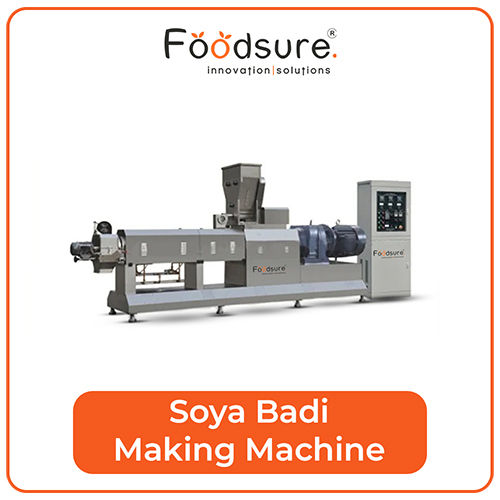

Soya Badi Making Machine Product Specifications

- Ring

- 1500 Kilograms (kg)

- ECO Friendly High Efficiency

- Free Stand

- Food Processors

- Soya Chunks Making Machine

- 1 Year

- Soya Chunks Making

- 500 Kg/hr

- 100 Watt (w)

- Yes

- PLC Control

- Stainless Steel

- Yes

Soya Badi Making Machine Trade Information

- Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA)

- 10 Piece Per Month

- 10 Days

- No

- Wooden Packaging | Shrink Wrap | Bubble Wrap

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India South India

- ISO 9001:2015

Product Description

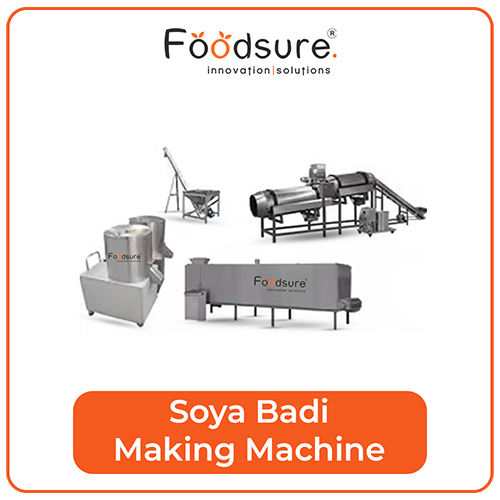

The Soya Badi Machine is a specific, high-speed, high-production capacity machinery for preparing textured soya protein called soya bari or soya nuggets. Soya Badi machines are highly specialized machinery and the process of Soya Badi Machines includes mixers, pre-conditioners, extruders, dryers, cooling conveyors, and packagers all of which yield quality soya bari covered by Soya Badi machines.

The process of the Soya Badi Machine begins with the mixer in which the raw soya flour is mixed with water and other ingredients to form a homogeneous mixture. The pre-conditioner in the Soya Badi Machine moisture and temperature are controlled to make this mixture have the right consistency that is suitable for extruding. Additionally, the extrusion process in the Soya Badi Machine is optimized to maintain the texture and nutritional value of the soya chunks, ensuring a high-quality final product with perfect use of the Soya Badi Machine.

In Soya Badi Machine, After it has been extruded the product is conveyed through the dryer section of the Soya Badi Machine to achieve the required moisture content. The cooling conveyor then cools the product at room temperature to prevent condensation during packing. The Soya Badi Machine also plays an important role in providing the final products with a homogenous shape/size and texture.

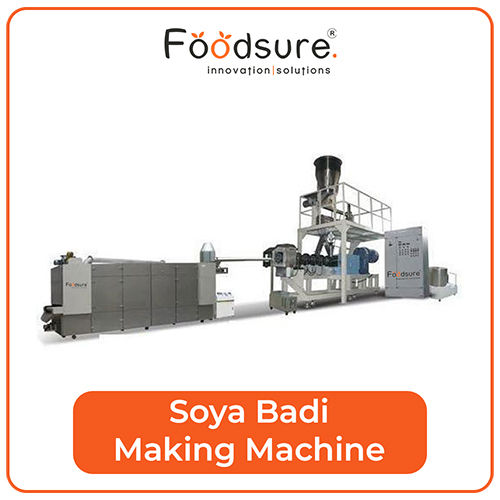

The Soya Badi Machine covers the whole process of making soya badi right from the point of adding ingredients to packing the packaged soya bari. Soya Badi Machine can make the soya bari packed in disinfected packets, which will keep it fresh for a long time. The mechanisms promised by the Soya Badi Machine ensure that standards are maintained by eliminating human input at every stage. For instance, no other machine carries quality checks for each step into production as seen from the Soya Badi Machine; therefore, the Soya Badi Machine suits consistent and hygienic production.

The Soya Badi Machine is equipped with enhanced control parameters for the manipulation of temperature, moisture content, and speed as desired for making soya bari. This is where the Soya Badi Machine comes in, as it provides much control over these parameters to enable high quality. Further, the structure of the whole Soya Badi Machine has been developed using SS 304 stainless steel, which makes it highly facile and secure for food.

Therefore, the Soya Badi Machine is a suitable method for preparing textured soya proteins. In this advanced system, there are mixers, pre-conditioners, extruders, dryers, cooling conveyors, and packaging of the Soya Badi machine that flow proficiently in every cycle to provide quality nuggets from the soya beans. For both extensive production lines of a company, right down to small operations of a local nature, the Soya Badi Machine guarantees unhampered production; a tool indispensable in the food production industry. With the Soya Badi Machine, producers ensure they work under high standards in terms of quality and output. All in all, the Soya Badi Machine is an ideal machine for any investor in soya meal food production. Soya Badi Machine can make a big difference.

Soya bari Machine

Soya badi Machine

Soya Badi making machine

Soya Badi plant

Soya Badi unit

Small Scale Soya Badi machine

Small Soya Badi machine

Fully Automatic Soya Badi Machine

Semi-Automatic Soya Badi Machine

200 kg per hour Soya Badi Machine

500 kg per hour Soya Badi Machine

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+