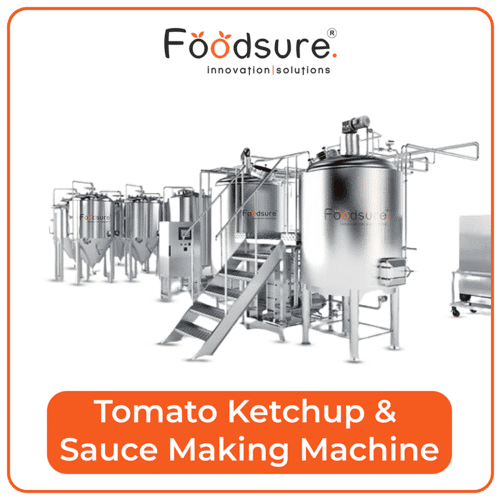

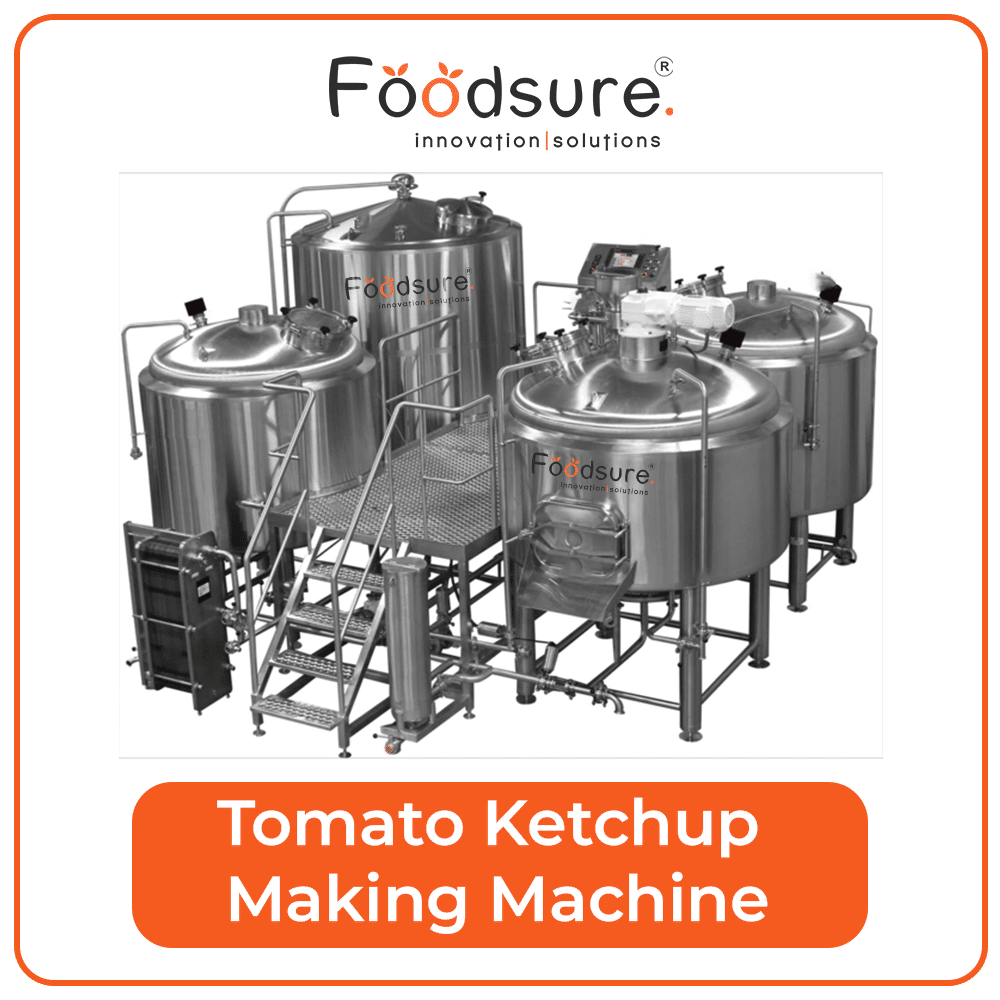

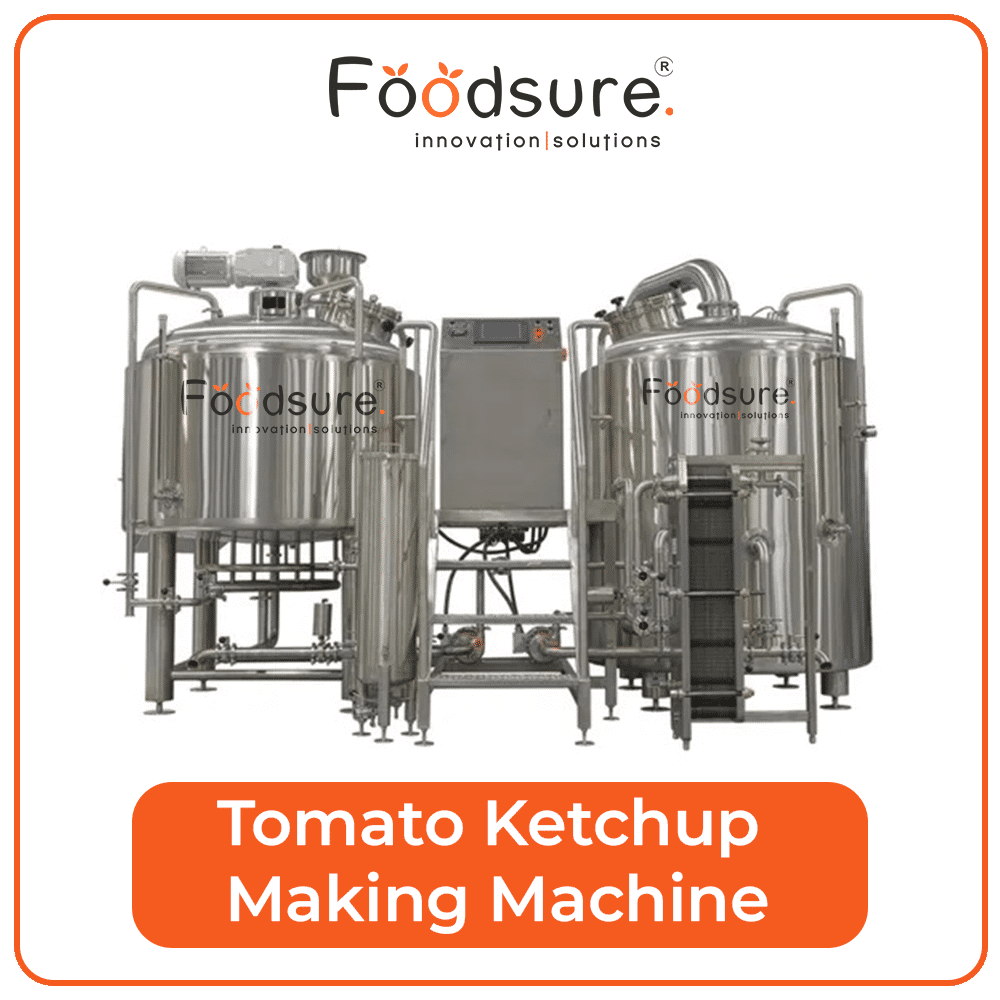

Tomato Ketchup Plant Manufacturer

1500000.00 INR/Unit

Product Details:

- Product Type Tomato Ketchup and Sauce

- General Use Industrial and Commercial

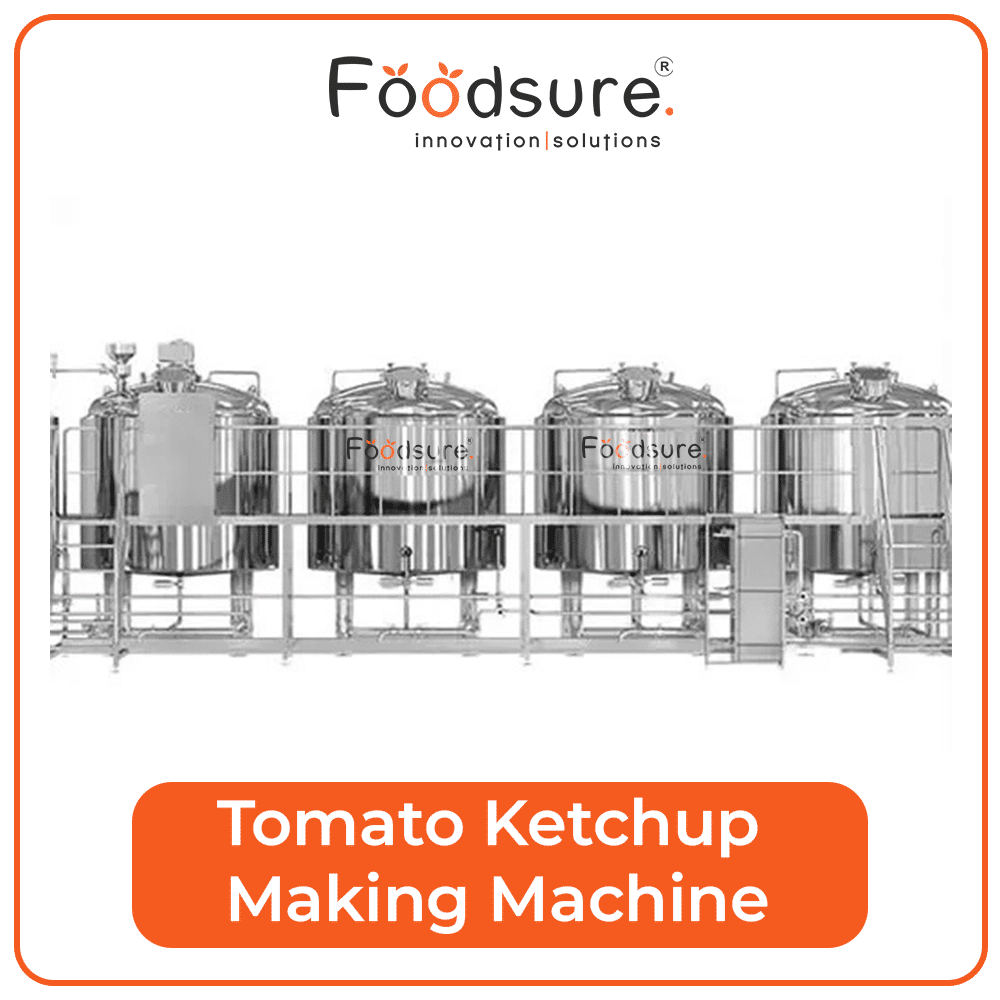

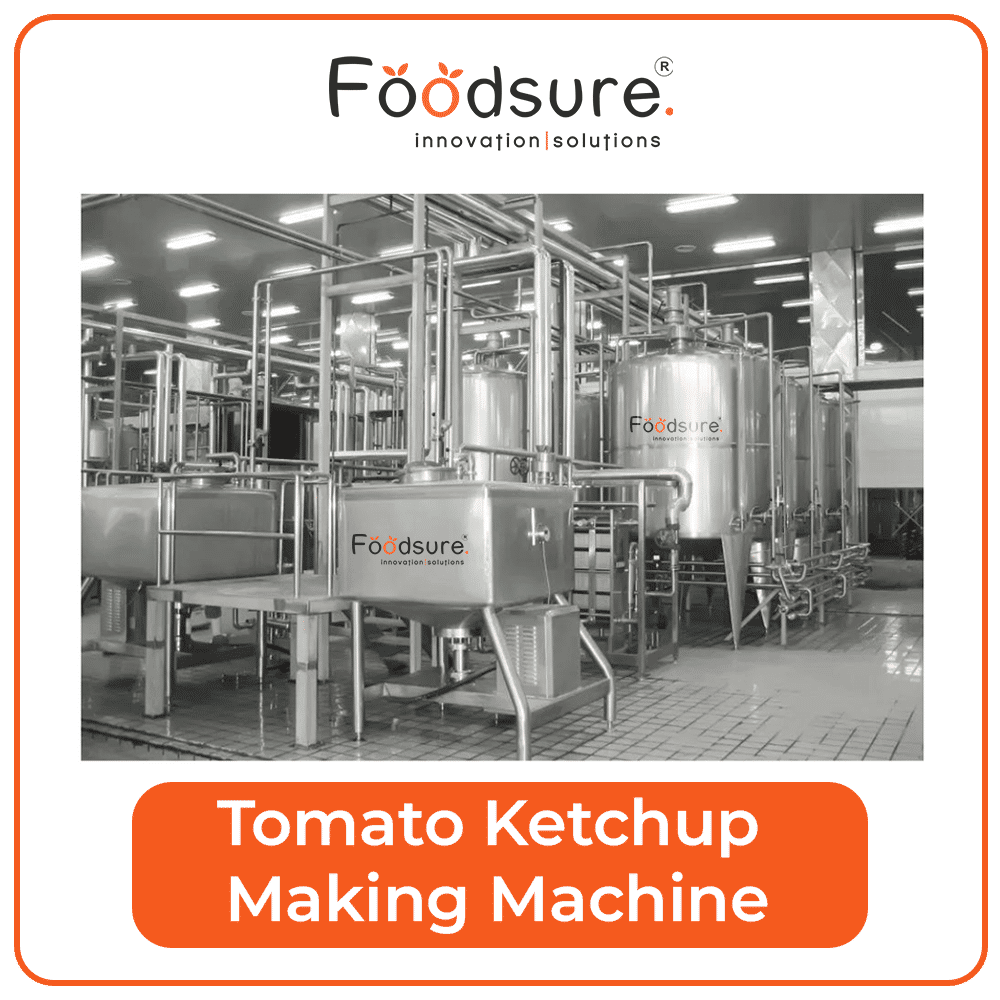

- Material Stainless Steel

- Capacity Upto 200 Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

X

Tomato Ketchup Plant Manufacturer Price And Quantity

- 1500000.00 INR/Unit

- 1 Unit

Tomato Ketchup Plant Manufacturer Product Specifications

- Industrial and Commercial

- Tomato Ketchup and Sauce

- Upto 200 Kg/hr

- Table Top

- Manual

- 20 Watt (w)

- Stainless Steel

- 1000 Kilograms (kg)

- Yes

- 420 Watt (w)

- Yes

- 1 Year

Tomato Ketchup Plant Manufacturer Trade Information

- New Delhi

- Paypal Cash Advance (CA) Cash in Advance (CID) Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packing And Bubble Rap Packing

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO9001:2015

Product Description

Our Tomato Ketchup Manufacturing Machine is designed for efficiency and precision. It incorporates advanced technology to handle various stages of ketchup production, including tomato processing, blending, heating, and packaging. With user-friendly controls and durable construction, it ensures consistent quality and output while minimizing manual intervention. This machine streamlines the manufacturing process, reducing labor costs and increasing productivity. It is built to meet industry standards for hygiene and safety, making it an ideal choice for food processing facilities looking to optimize their ketchup products.

-

Types of Ketchup-

- Regular Tomato Ketchup: This is the classic and most common type of tomato ketchup that you can find in most supermarkets. It has a slightly sweet and tangy flavor and a smooth consistency.

- Spicy Tomato Ketchup: This type of ketchup has a bit of heat to it, typically from the addition of chili peppers or other spicy ingredients.

- Organic Tomato Ketchup: This type of ketchup is made from organically grown tomatoes and other ingredients that are free from pesticides and synthetic fertilizers.

- Low-Sugar Tomato Ketchup: This type of ketchup has less sugar than regular tomato ketchup and is a good option for people who are watching their sugar intake.

- No-Salt Tomato Ketchup:This type of ketchup is made without added salt, which can be a good option for people who are watching their sodium intake.

- Flavored Tomato Ketchup:Some manufacturers add additional flavors to their tomato ketchup, such as garlic, onion, or spices, to give it a unique taste.

- Process flow chart for making tomato ketchup:

- Raw Material Reception: Fresh tomatoes are received and inspected for quality.

- Cleaning and Sorting: The tomatoes are thoroughly cleaned to remove dirt and debris. They are then sorted to remove any damaged or spoiled tomatoes.

- Chopping and Crushing: The cleaned tomatoes are chopped into smaller pieces and then crushed to form a pulp.

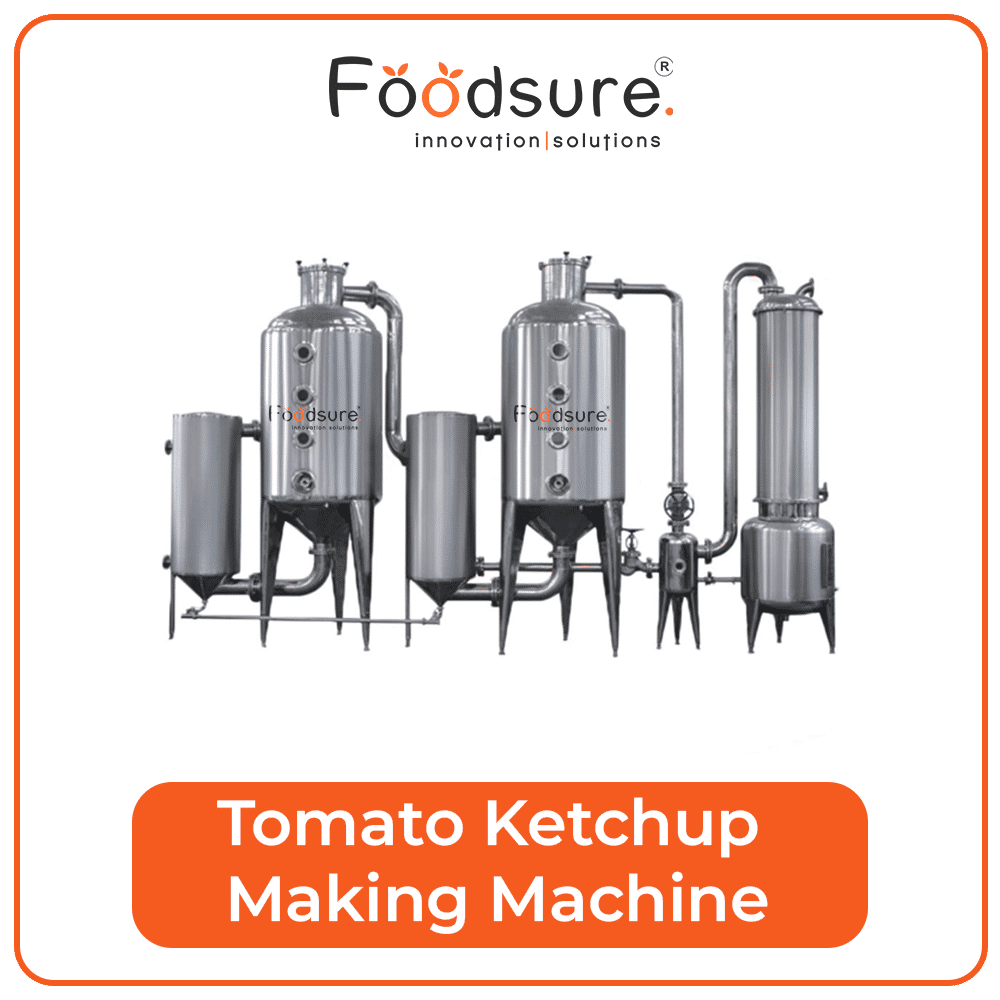

- Heating: The tomato pulp is heated to a specific temperature to facilitate the extraction of juice and to kill any harmful bacteria present.

- Straining: The heated tomato pulp is strained to remove seeds, skin, and any remaining solids, resulting in a smooth tomato puree.

- Mixing: The tomato puree is mixed with other ingredients such as sugar, vinegar, salt, and spices to achieve the desired flavor profile.

- Cooking: The mixture is cooked at high temperatures to thicken the ketchup and develop its characteristic flavor.

- Cooling: The cooked ketchup is cooled down rapidly to prevent spoilage and maintain freshness.

- Packaging: The cooled ketchup is filled into bottles or containers, sealed, and labeled.

- Quality Control: Samples of the finished product are tested for quality, including taste, texture, color, and shelf life.

- Storage: The packaged ketchup is stored in a controlled environment to maintain its quality until it is ready to be shipped to retailers or distributors.

- Distribution: The finished tomato ketchup is distributed to supermarkets, grocery stores, restaurants, and other food service establishments for sale to consumers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Processing Machines' category

Back to top