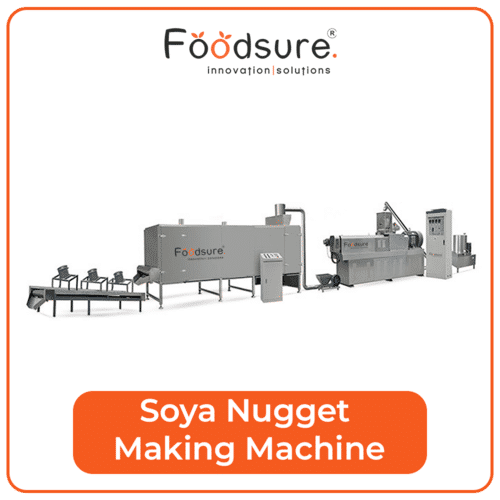

Soya nuggets production capacity

Product Details:

- Product Type Soya nuggets production capacity

- General Use Industrial and Commercial

- Material Stainless Steel

- Capacity upto 500 kg Kg/hr

- Automatic Yes

- Control System PLC Control

- Voltage 420 Volt (v)

- Click to View more

Soya nuggets production capacity Price And Quantity

- 2500000.0 INR/Unit

- 1 Pieces

Soya nuggets production capacity Product Specifications

- Industrial and Commercial

- Stainless Steel

- PLC Control

- upto 500 kg Kg/hr

- 420 Volt (v)

- 1 Year

- Yes

- Soya nuggets production capacity

- 120 Watt (w)

Soya nuggets production capacity Trade Information

- New Delhi

- Paypal Cash Advance (CA) Cash in Advance (CID) Cheque

- 5 Pieces Per Month

- 30 Days

- Yes

- Wooden packaging & Shrink Wrapping

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015

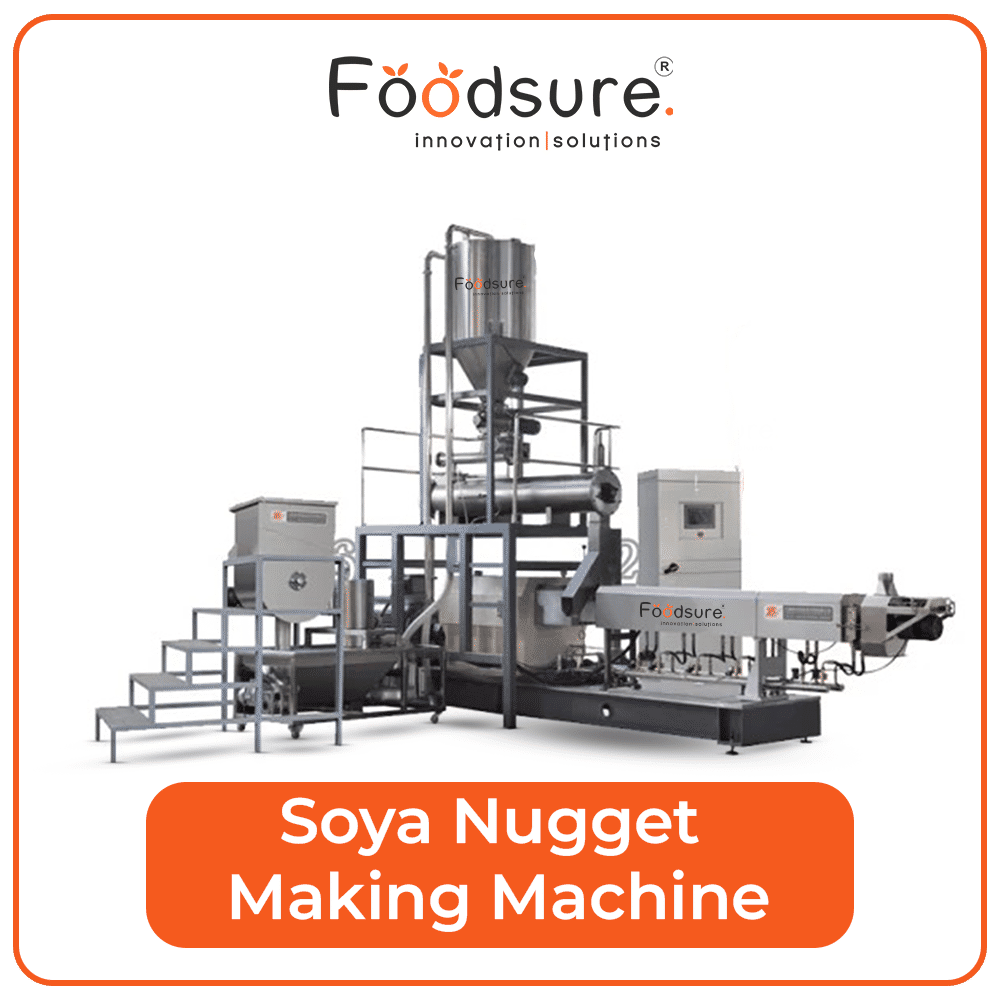

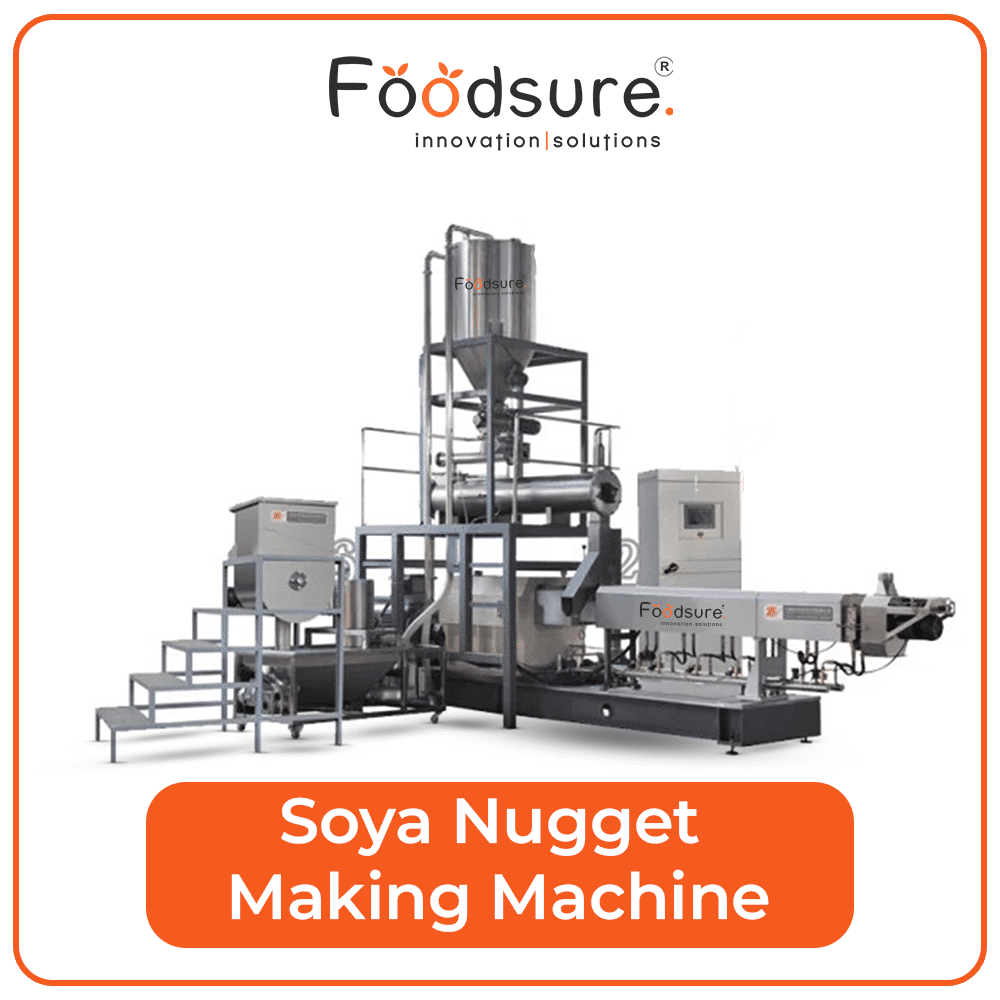

Product Description

Soya Nuggets Production Capacity

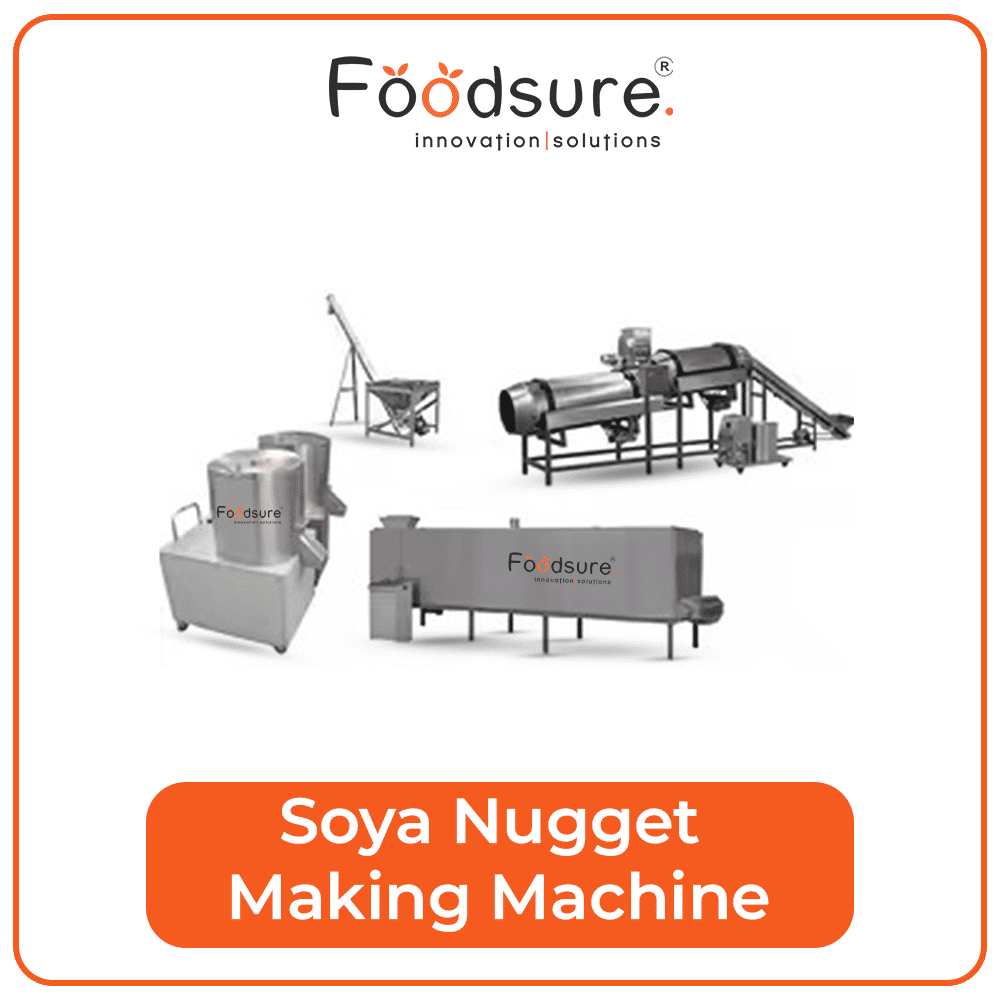

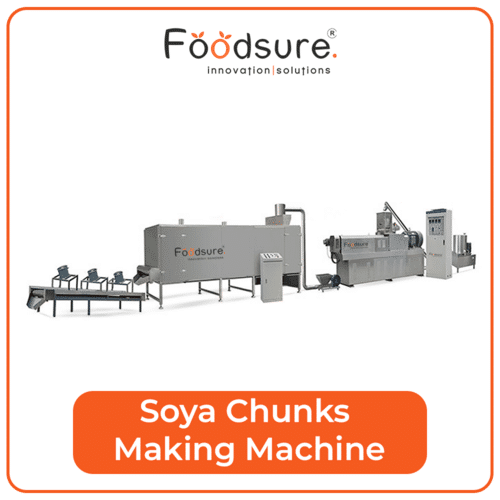

The production of soya nuggets involves several key machines, ensuring efficient processing and high-quality products. Below is a detailed look at the machines used in the soya nuggets production process:

Premixer: In the process of soya nuggets manufacturing, the Premixer is very vital in mixing some of the inputs comprising soybean flour, and other chemicals to make perfect soya nuggets. This stabilizes the dispersion to make sure that an appropriate blend for making uniform soya nuggets is attained.

Conditioner: When mixing in the process of soya nuggets, the material is taken through the Conditioner. The conditioner is responsible for the regulation of the right moisture content and temperature of the soya nuggets through the process of extrusion.

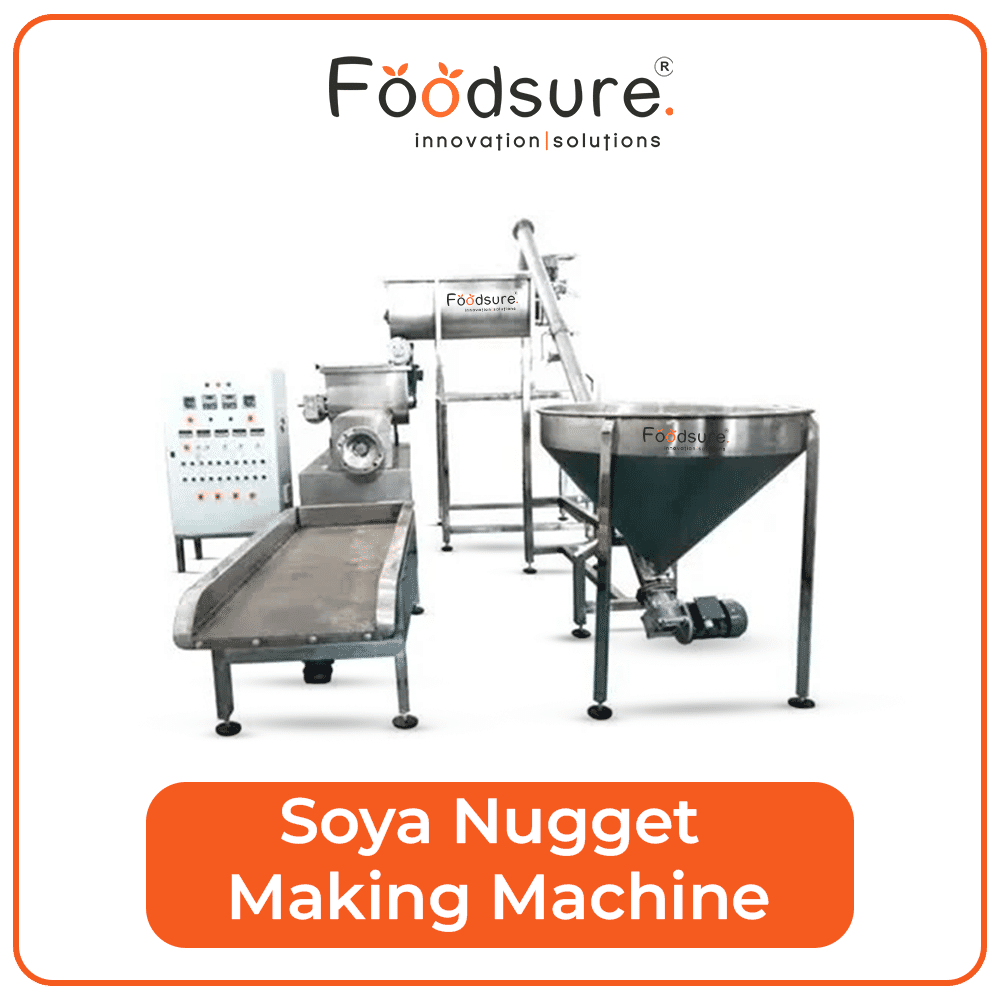

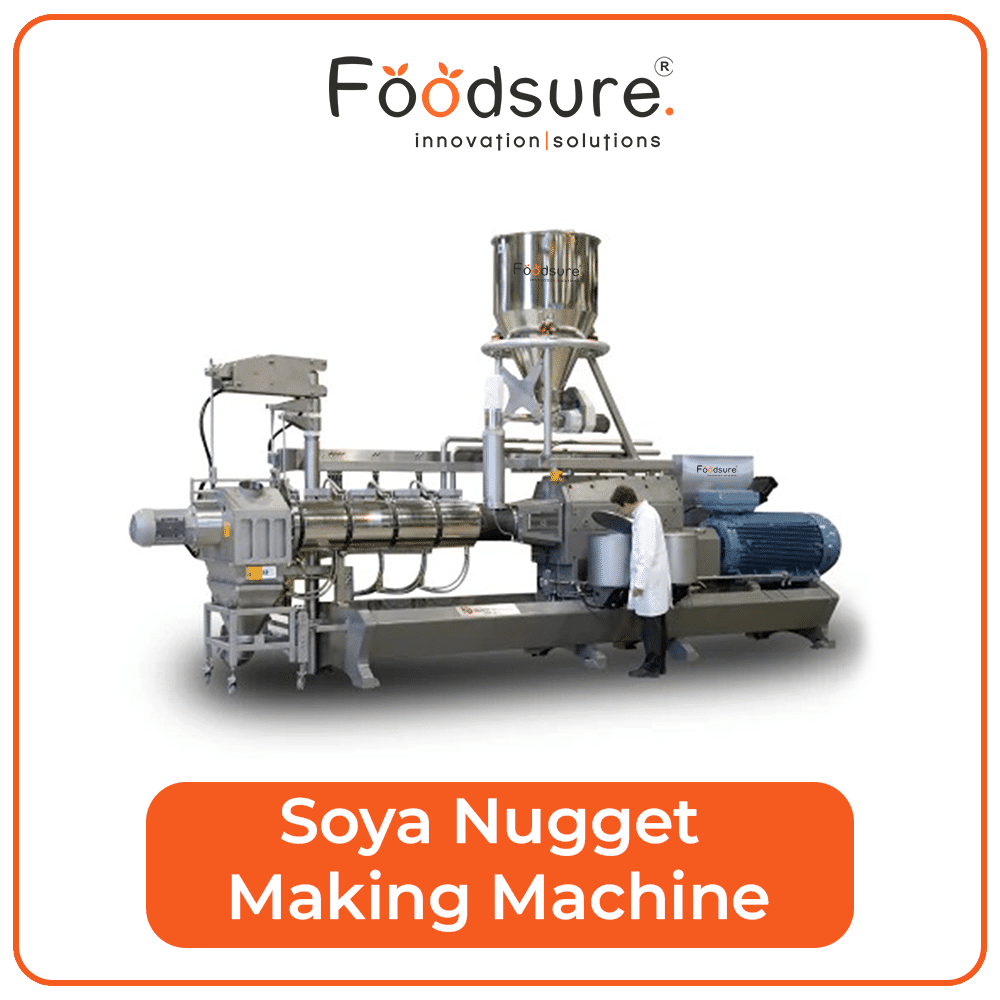

Extruder: The Extruder is the most important machine used in the production of soya nuggets. High pressure and heat to shape the raw material into nugget form, to make the soya nuggets have the right texture and consistency.

Conveyor: After the formation of the soya nuggets the finished product is then conveyed between production stages using a Conveyor. This system equally ensures that there is order and smooth running throughout the soya nuggets production process.

Dryer: The Dryer is used to remove excess moisture from the soya nuggets. This step is vital to the accomplishment of the required texture in soya nuggets, in addition to elongating the shelf life of the soya nuggets.

Cooling Conveyor: The soya nuggets are then conveyed to the Cooling Conveyor where their temperature is controlled to an acceptable level after soya nuggets are dried. This also aids in maintaining the tenderness of the soya nuggets, and ready them for packaging.

Storage Tank: In high capacity, the soya nuggets are subjected to a Storage Tank before being them to packagers. This makes certain that there is always a production buffer and also plays an important role in maintaining stable production.

Packaging Machine of Soya nuggets: The last process of the soya nuggets manufacturing process is the packaging. The Packaging Machine plays a critical role in packing the soya nuggets to the right packaging size and quality for distribution.

Soya nuggets: By using the perfect machinery soya nugget production is highly effective and with standard quality. Making decisions such as who should produce the Premixer, how to select the qualified employees, the techniques used in the Preconditioning, and all aspects involved in the designing the packaging material involved in the overall creation of the soya nuggets that help to meet the expected standards of the soya nuggets industry these machines make sure the complete efficiency and profitability of soya nuggets with quality control.

Therefore the selection of the right kind of machines in the Soya nuggets production line does not only manage the flow but also the quality of the soya nuggets in terms of texture, taste, and longevity. Manufacturers that focus on optimizing each step of the process of the soya nuggets can achieve consistent product quality and meet consumer expectations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+