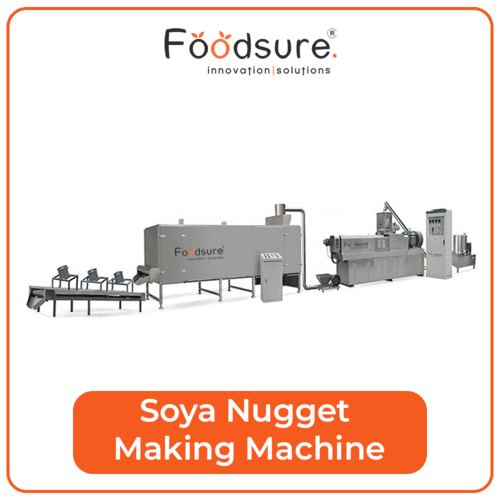

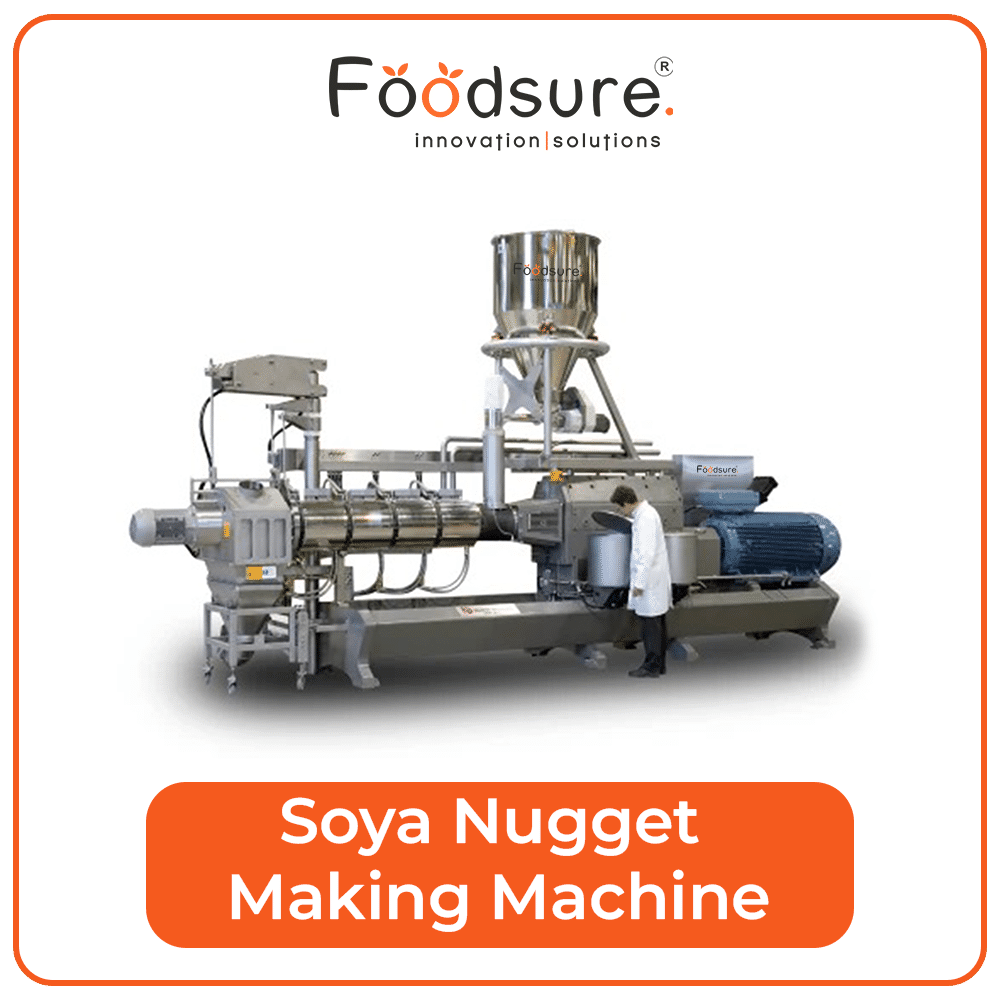

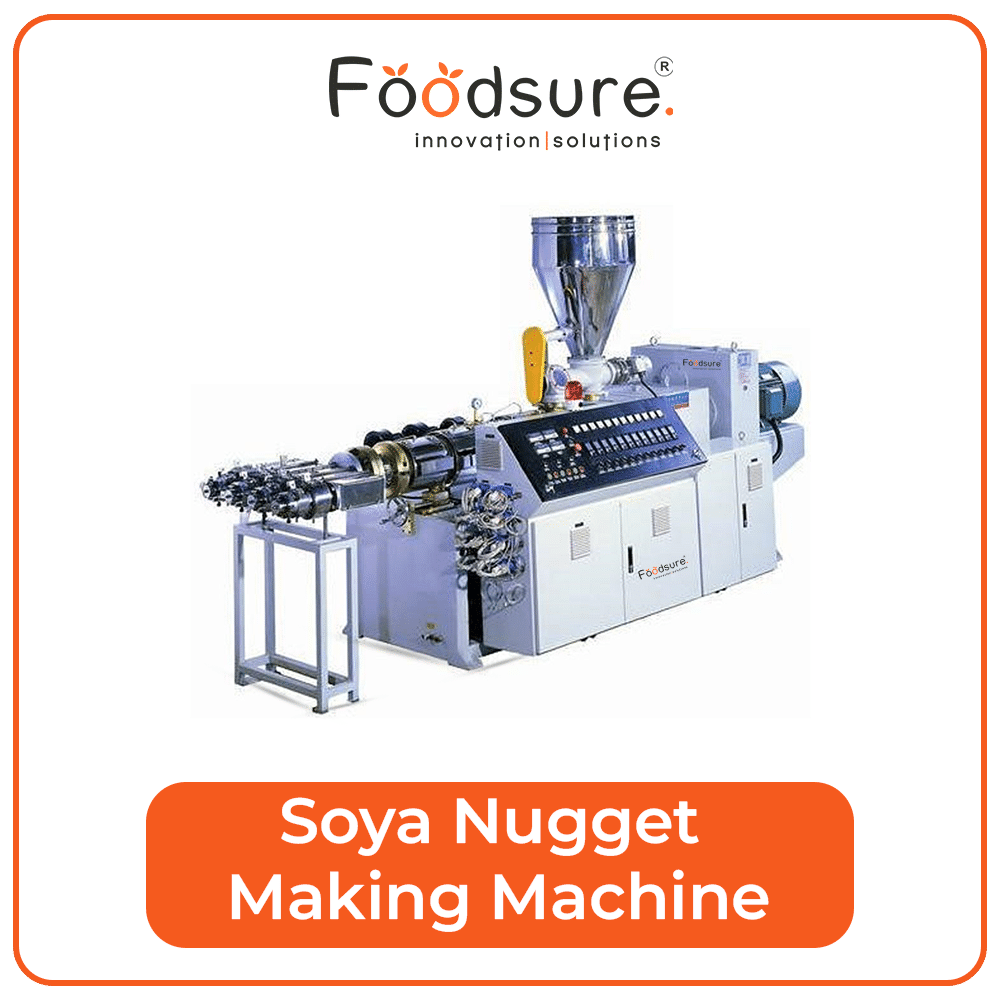

Soya Nuggets Extruder Machine

Product Details:

- Product Type Soya Nuggets

- General Use Industrial and Commercial

- Material Stainless Steel

- Capacity 2000 Kg/hr

- Automatic Yes

- Control System PLC Control

- Voltage 420 Volt (v)

- Click to View more

Soya Nuggets Extruder Machine Price And Quantity

- 1

- 2500000.0 INR/Unit

Soya Nuggets Extruder Machine Product Specifications

- Industrial and Commercial

- 2000 Kg/hr

- Yes

- Stainless Steel

- 1 Year

- PLC Control

- Soya Nuggets

- 420 Volt (v)

- 120 Watt (w)

- ECO Friendly Low Noice

Soya Nuggets Extruder Machine Trade Information

- New Delhi

- Cash Against Delivery (CAD) Paypal Cash Advance (CA) Cash in Advance (CID) Cheque

- 5 Per Month

- 30 Days

- Wooden Packaging & Shrink Wrapping

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015, CE

Product Description

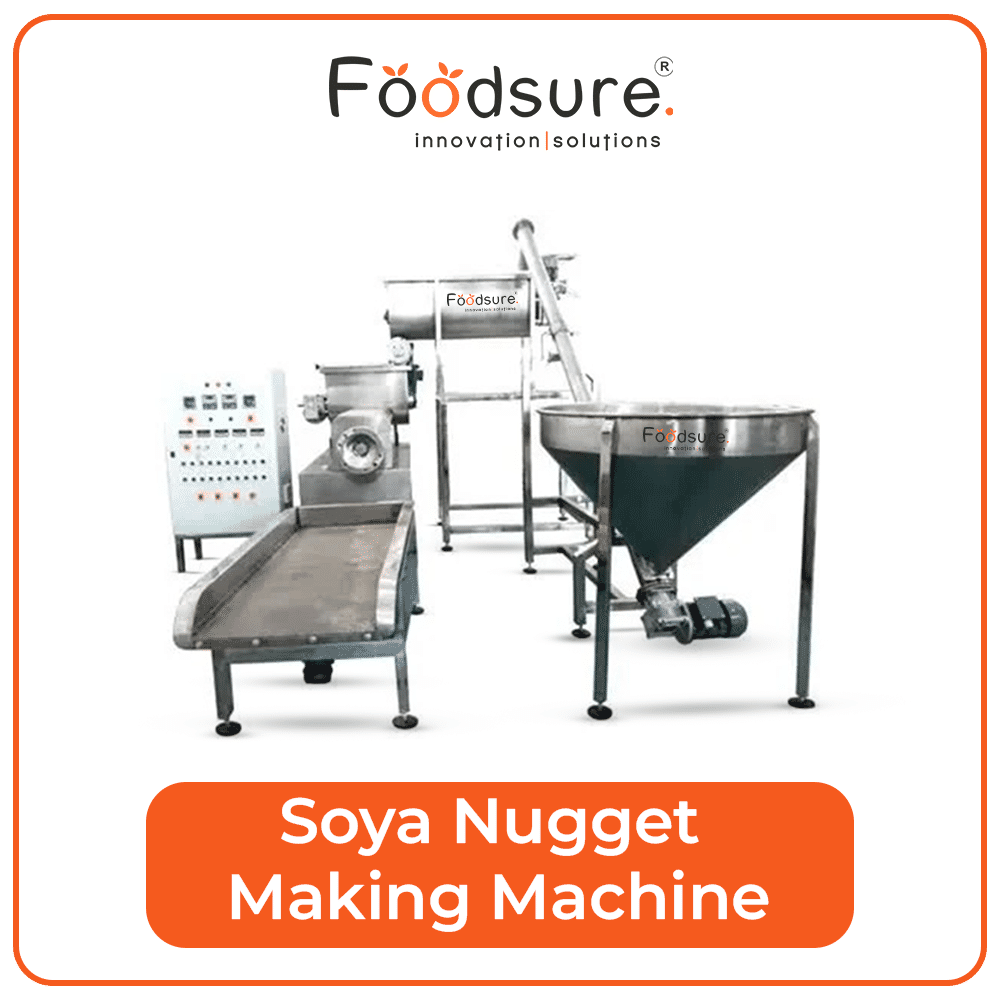

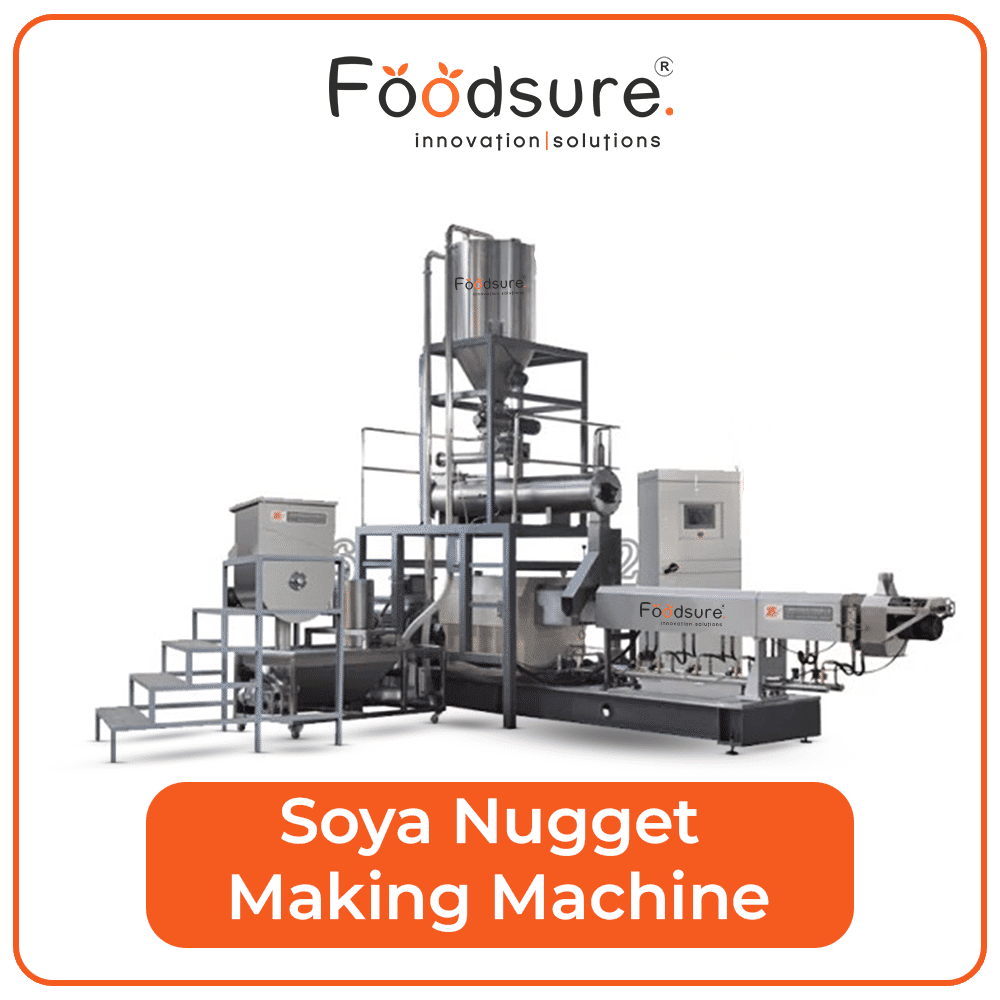

The Soya Nugget Machine is among the well-developed machinery for the production of soya nuggets or textured vegetable protein (TVP). This Soya Nugget Machine incorporates all these parts to enable efficiency and quality production of the soya nuggets.

Key Components of the Soya Nugget Machine

Mixers: The Soya Nugget Machine starts with industrial mixers, that is, mixing soya flour with water and other ingredients. There is also convenience and speed here in the Soya Nugget Machine mixers so the base material can be homogenized before it goes for the next step in the Soya Nugget Machine production process. Since it makes it possible to have a standard mixture, the Soya Nugget Machine lays a good basis for the production of soya nuggets.

Pre Conditioners: In this process of the Soya Nugget Machine, pre-conditioners are used to hydrate and condition the mixture for extrusion. This step is important for the right texture and consistency of the final product in the Soya Nugget Machine. The pre-conditioners in the Soya Nugget Machine ensure that each nugget will meet the right moisture content to allow for extrusion. Soya Nugget Machine is game-changing.

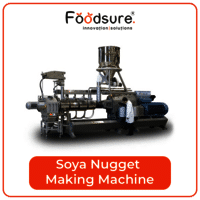

Extruders: In Soya Nugget Machine, The extruder is one of the significant components of the Soya Nugget Machine. In this machine, it cooks and shapes under heat and pressure the soya mixture to achieve the nugget look of soya.

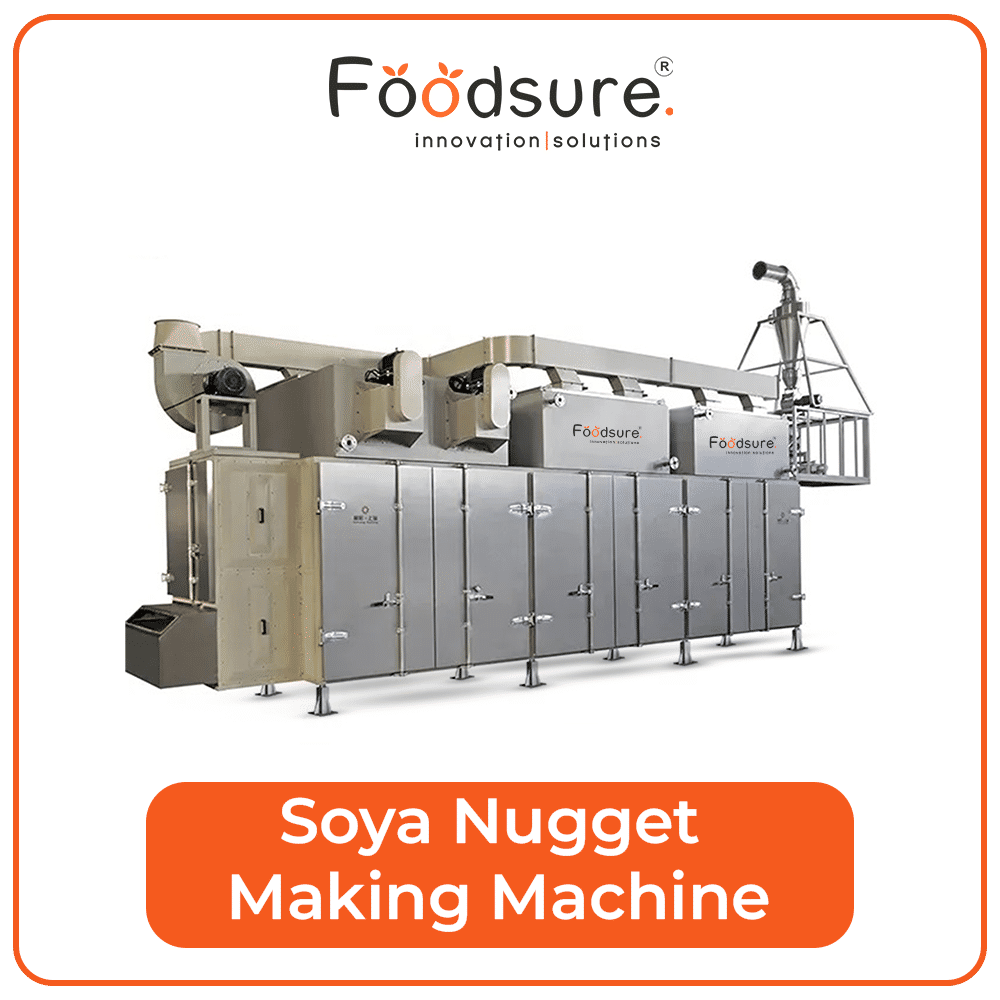

Dryers: After extrusion, the Soya Nugget Machine transports the nuggets through dryers. These machines in Soya Nugget Machines take the nuggets through another process where moisture is eliminated from them to ensure they last long and are ready to pack.

Cooling Conveyors: For flow ability the Soya Nugget Machine offers cooling conveyors that adequately cool the nuggets after drying. Making up this critical part of the Soya Nugget Machine helps in setting the nugget structure to avoid any crumbling when they cool. The cooling system of the Soya Nugget Machine is one of the most significant factors in the quality of the end products since it is a basic structure in the production process.

Packaging Machines: The last of the process of the Soya Nugget Machine is the packaging of the Soya nuggets. Through the Soya Nugget Machine, the nuggets are packed in well sealed bags reducing the probability of contact with extraneous bodies and exposure to air. This is the last step of the Soya Nugget Machine to ensure that Soya Nuggets are in perfect condition to reach consumers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+