Welcome to Foodsure!

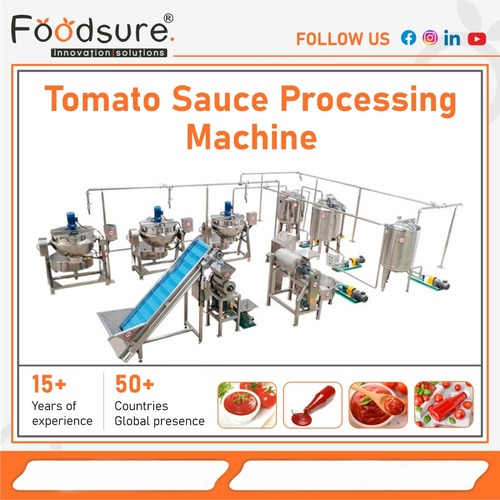

Sauces Plant Setup

500000.00 INR/Unit

Product Details:

- Product Type Sauces

- General Use Industrial and Commercial

- Material Stainless Steel

- Capacity Upto 3000 Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

X

Sauces Plant Setup Price And Quantity

- 1 Unit

- 500000.00 INR/Unit

Sauces Plant Setup Product Specifications

- Table Top

- 20 Watt (w)

- 1 Year

- Yes

- 420 Watt (w)

- 1000 Kilograms (kg)

- Manual

- Yes

- Stainless Steel

- Industrial and Commercial

- Upto 3000 Kg/hr

- Sauces

Sauces Plant Setup Trade Information

- New Delhi

- Cheque Paypal Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID)

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Pouch Packaging, Pet Bottle Packaging

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO9001:2015

Product Description

Setting up a sauces plant involves creating a facility where various types of sauces are produced. Here a human-friendly description of the process:

- Location Selection:Choose a suitable location for the plant, considering factors like access to raw materials, transportation, and a skilled workforce.

- Facility Design:Design the plant layout to include different sections for sauce production, packaging, storage, and quality control.

- Equipment Installation:Install specialized equipment like mixers, kettles, filling machines, and packaging units to facilitate the sauce-making process.

- Ingredient Handling:Set up systems for handling and storing raw materials such as spices, vegetables, oils, and other ingredients needed for making the sauces.

- Production Process:Develop recipes and procedures for making various types of sauces, ensuring consistency in taste and quality.

- Quality Control:Implement quality control measures to monitor the production process, conduct testing, and ensure that the sauces meet safety and quality standards.

- Packaging and Distribution:Establish packaging lines to bottle or package the sauces efficiently and prepare them for distribution to retailers or consumers.

- Regulatory Compliance:Ensure compliance with food safety regulations, sanitation standards, and other industry requirements to operate the sauces plant legally and safely.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

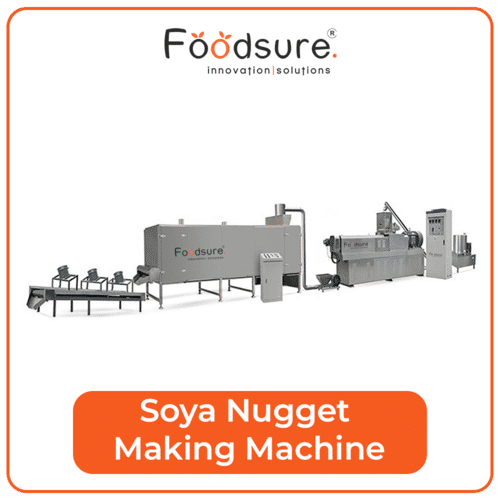

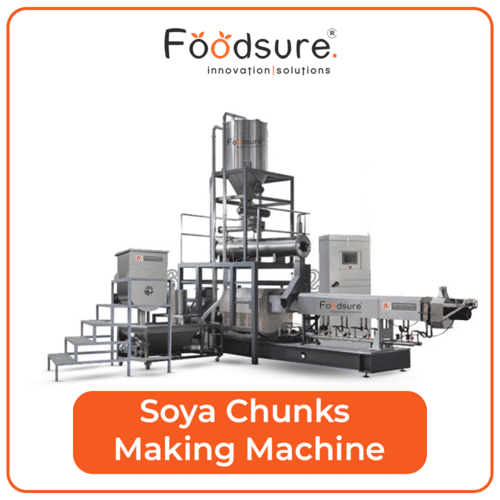

Other Products in 'Processing Machines' category

Back to top