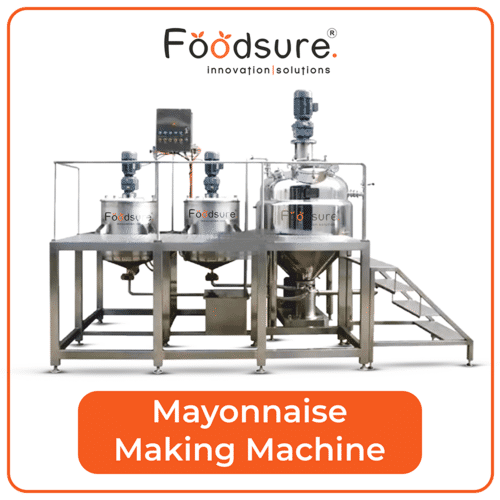

Mayonnaise Plant

Product Details:

- Product Type Mayonnaise Emulsions

- General Use Commercial, Industrial

- Material Stainless Steel

- Capacity upto 3000 Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to View more

Mayonnaise Plant Price And Quantity

- 500000.00 INR/Unit

- 1 Unit

Mayonnaise Plant Product Specifications

- 20 Watt (w)

- 440 V Watt (w)

- 1 year

- Stainless Steel

- Manual

- 1000 Kilograms (kg)

- Yes

- Table Top

- Mayonnaise Emulsions

- Commercial, Industrial

- ECO Friendly Low Noice Lower Energy Consumption Compact Structure High Efficiency

- Yes

- upto 3000 Kg/hr

Mayonnaise Plant Trade Information

- New Delhi

- Paypal Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging, Bubble Wrap

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO 9001:2015

Product Description

Foodsure offers state-of-the-art mayonnaise plant solutions designed to streamline production and ensure the highest quality output. Our mayonnaise plants are equipped with cutting-edge machinery and technology to efficiently process and package mayonnaise products.From emulsification to pasteurization and packaging, our plants are designed to handle every stage of the production process with precision and consistency. We prioritize food safety and adhere to strict quality control measures to ensure that our mayonnaise products meet the highest industry standards.Our mayonnaise plants are versatile and customizable to accommodate different production capacities and product variations. Whether you're producing traditional mayonnaise, flavored variants, or specialty formulations, our plants can be tailored to suit your specific requirements.

With Foodsure's mayonnaise plant solutions, you can expect:

- Efficient production: Our plants are designed for optimal efficiency, allowing you to maximize productivity and minimize downtime.

- Consistent quality: We maintain rigorous quality control measures throughout the production process to ensure that every batch meets your quality standards.

- Flexibility: Our plants are adaptable to accommodate changes in production requirements, allowing you to scale up or down as needed.

- Innovative technology: We leverage the latest technology and innovation to optimize plant performance and enhance product quality.

- Expert support: Our team of experienced professionals provides comprehensive support, from initial plant design to installation, training, and ongoing maintenance.

- Whether you're a small-scale producer or a large manufacturing facility, Foodsure's mayonnaise plant solutions offer a reliable and cost-effective solution for your production needs. Partner with us and take your mayonnaise production to the next level.

Foodsure's Mayonnaise Plant is a state-of-the-art facility equipped with cutting-edge machines and technology to ensure the production of high-quality mayonnaise products. Here's a detailed description of the machines used in our plant:

- Mixer/Blender: At the heart of our production process is the mixer or blender. This machine is responsible for blending the key ingredients of mayonnaise, including oil, vinegar or lemon juice, egg yolks, and seasonings. The mixer ensures thorough and uniform mixing to achieve the desired texture and flavor profile.

- Emulsifier: Emulsification is a crucial step in mayonnaise production, as it ensures the stable suspension of oil droplets in the water-based ingredients. Our emulsifier utilizes advanced technology to achieve optimal emulsification, resulting in a smooth, creamy texture that is characteristic of high-quality mayonnaise.

- Pasteurizer: Pasteurization is essential for food safety and shelf-life extension. Our pasteurization equipment heats the mayonnaise mixture to a specific temperature for a set period, effectively killing harmful microorganisms while preserving the product's freshness and flavor. This ensures that our mayonnaise products are safe for consumption and have an extended shelf life.

- Filling Machine: Once the mayonnaise is mixed and pasteurized, it is ready for packaging. Our filling machine automates the filling process, accurately dispensing the mayonnaise into containers such as jars, bottles, or pouches. This ensures consistent fill levels and minimizes product waste, leading to cost savings and increased efficiency.

- Labeling Machine: Proper labeling is crucial for product identification, branding, and regulatory compliance. Our labeling machine applies labels to the packaging containers, including essential information such as product name, ingredients, nutritional information, and expiration date. This ensures that consumers have access to accurate and transparent information about our mayonnaise products.

- Capping Machine: After filling, the packaging containers are sealed with caps or lids using our capping machine. This step ensures product integrity and freshness by preventing contamination and leakage. Our capping machine is capable of handling various types of closures, including screw caps, flip-tops, and press-on lids, to accommodate different packaging formats.

- Conveyor System: To streamline the production process, we utilize a conveyor system to transport containers between different stages of production. This includes moving containers from the filling machine to the capping machine, as well as transferring finished products to the packaging area for labeling and distribution. The conveyor system ensures smooth workflow and minimizes manual handling, increasing overall efficiency.Overall, our Mayonnaise Plant is equipped with advanced machines and technology to ensure the production of high-quality mayonnaise products that meet the highest standards of safety, quality, and consistency. Our commitment to excellence in manufacturing allows us to deliver premium mayonnaise products that delight consumers and exceed their expectations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+