Mayonnaise Making Machine

Product Details:

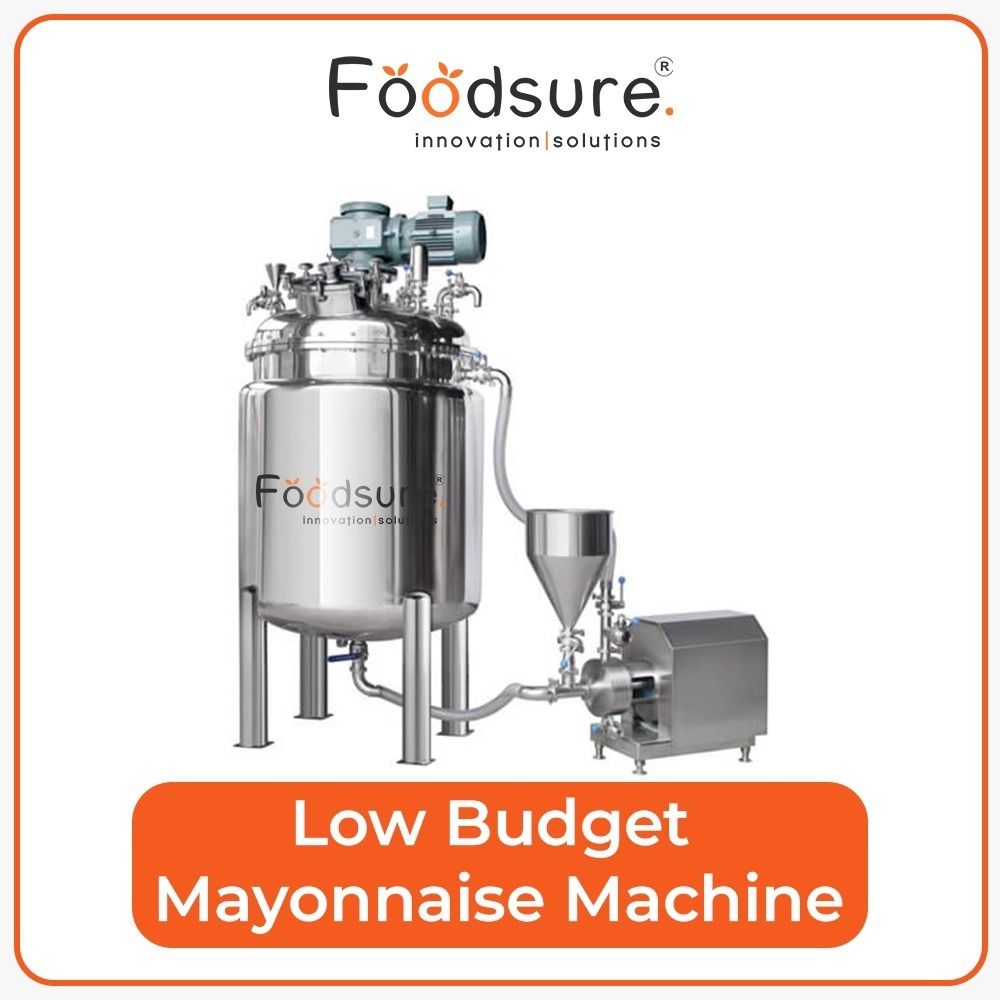

Mayonnaise Making Machine Price And Quantity

- 1 Unit

- 2000000 INR/Unit

Mayonnaise Making Machine Trade Information

- Others

- 30 Days

- Yes

- If order is confirmed we will reimburse the sample cost

- As per requirment

Product Description

Mayonnaise Making Machine

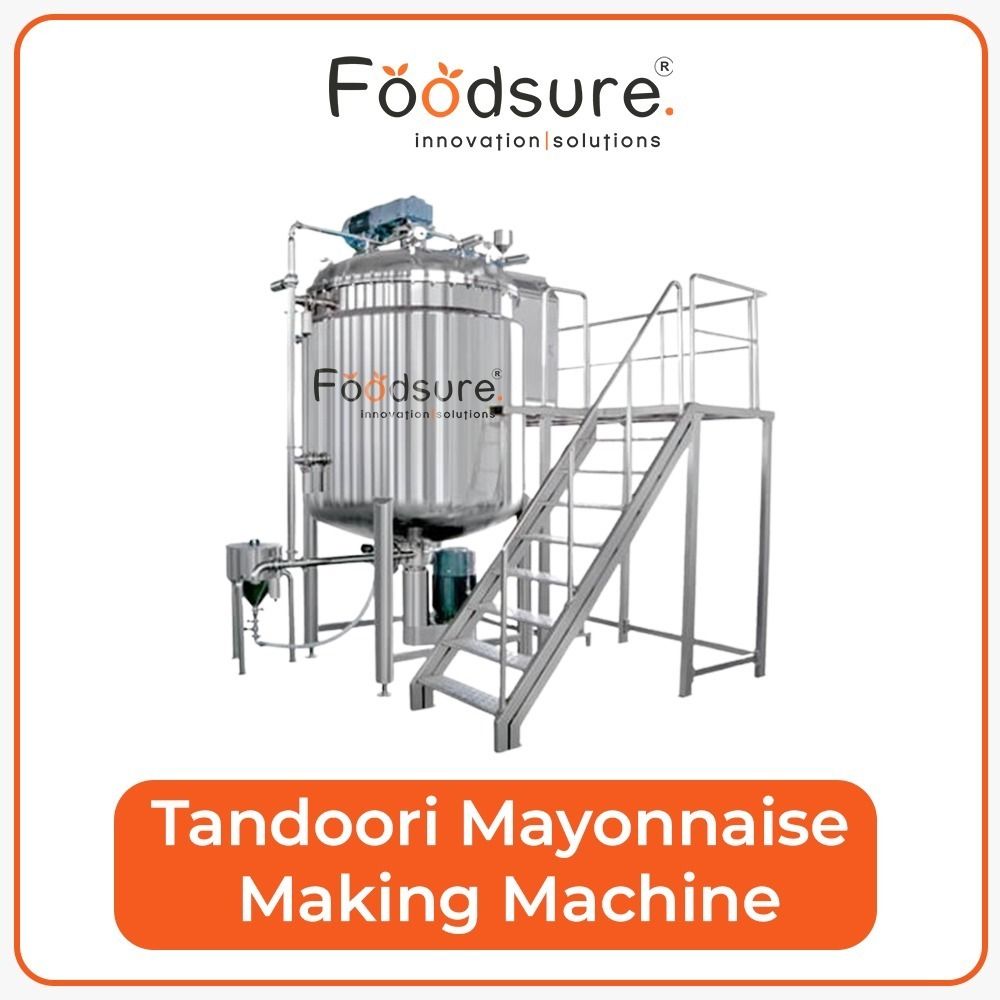

People enjoy their meal with additional sauces and mayonnaise. Be it with momos, pasta, or even with normal parathas, mayo becomes the choice of many. Thus, mayonnaise becomes a favourite of everyone. Due to advancements in technology, mayonnaise-making machines are at their peak.

Stages in the Mayonnaise Manufacturing Process:

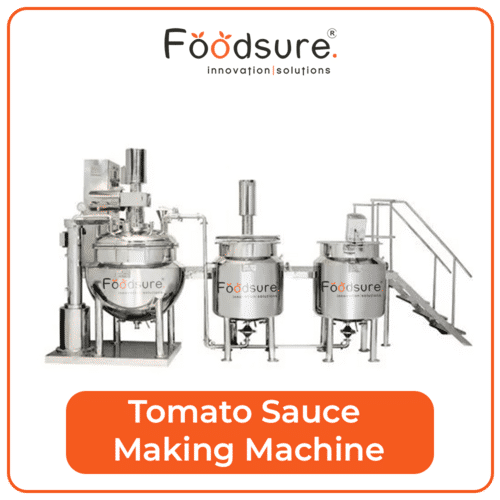

We begin the process with the preparation of the main ingredients such as vegetable oil, egg yolks, and an acidic component (vinegar or lemon juice), which is the first move in making mayonnaise. The most important function of a mayonnaise manufacturer is the emulsification.

In this stage, we mix oil into egg yolks and water. After the basic mixture is done, salt, sugar, and mustard are added.

To ensure product safety and increase shelf life, the mayonnaise is pasteurized. The mayonnaise goes through careful testing. Once the mayonnaise passes all quality checks, it is moved to the packaging process. The outcome of the product is then stored at a managed temperature until they are distributed to retail locations or directly to the consumers.

Foodsure manufactures mayonnaise mixers for small-scale and large-scale production of mayonnaise, making the effort smooth, and quality preserves the feel of a homey kitchen recipe.