Mayonnaise Consultant

Product Details:

Mayonnaise Consultant Price And Quantity

- 1 Unit

- 200000.00 INR/Unit

Mayonnaise Consultant Trade Information

- New Delhi

- Paypal Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- As Per Customer

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

- ISO9001:2015

Product Description

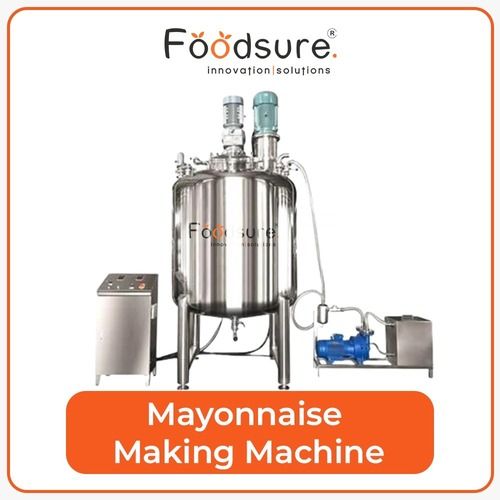

Mayonnaise machines Consultants are specialized equipment used to mix, emulsify, and package mayonnaise in large quantities. These machines are typically used in industrial food production settings, such as factories or commercial kitchens, where high volumes of mayonnaise need to be produced efficiently. Mayonnaise machines can vary in size and complexity, from small tabletop models to large, fully automated systems. Some machines are designed specifically for mixing and emulsifying the ingredients in mayonnaise, while others are designed for both mixing and packaging. The mixing process typically involves combining oil, vinegar or lemon juice, and other ingredients in a large mixing bowl or tank. The ingredients are then blended together using high-speed rotating blades or paddles until a smooth and creamy emulsion is formed. Once the mayonnaise is mixed, it can be pumped into packaging containers, such as jars or squeeze bottles, using filling machines. These machines can be manual or fully automated, depending on the volume of production and the level of precision required. Overall, mayonnaise machines play a crucial role in streamlining the production of mayonnaise in large-scale food production settings. They help to ensure consistency and efficiency in the mixing and packaging process, while also reducing labor costs and improving food safety standards. As an AI language model, I do not have access to the most current market reports, as they are not available in my training data.

Mayonnaise is a popular condiment that is widely used in various food applications. According to a report by Research and Markets, the global mayonnaise market was valued at $10.6 billion in 2020 and is expected to grow at a CAGR of 4.2% from 2021 to 2028.

The growth of the mayonnaise market is driven by factors such as the increasing demand for convenience foods, changing consumer preferences for different flavors and textures, and the growing popularity of plant-based mayonnaise products. However, factors such as health concerns related to the high-fat content of mayonnaise and the availability of alternative condiments such as salsa, ketchup, and mustard could limit the growth of the market.

Overall, the mayonnaise market is expected to continue growing in the coming years, driven by the increasing demand for convenience foods and the introduction of new flavors and formulations to cater to changing consumer preferences. Here are some of the machines that may be used in the mayonnaise production process.

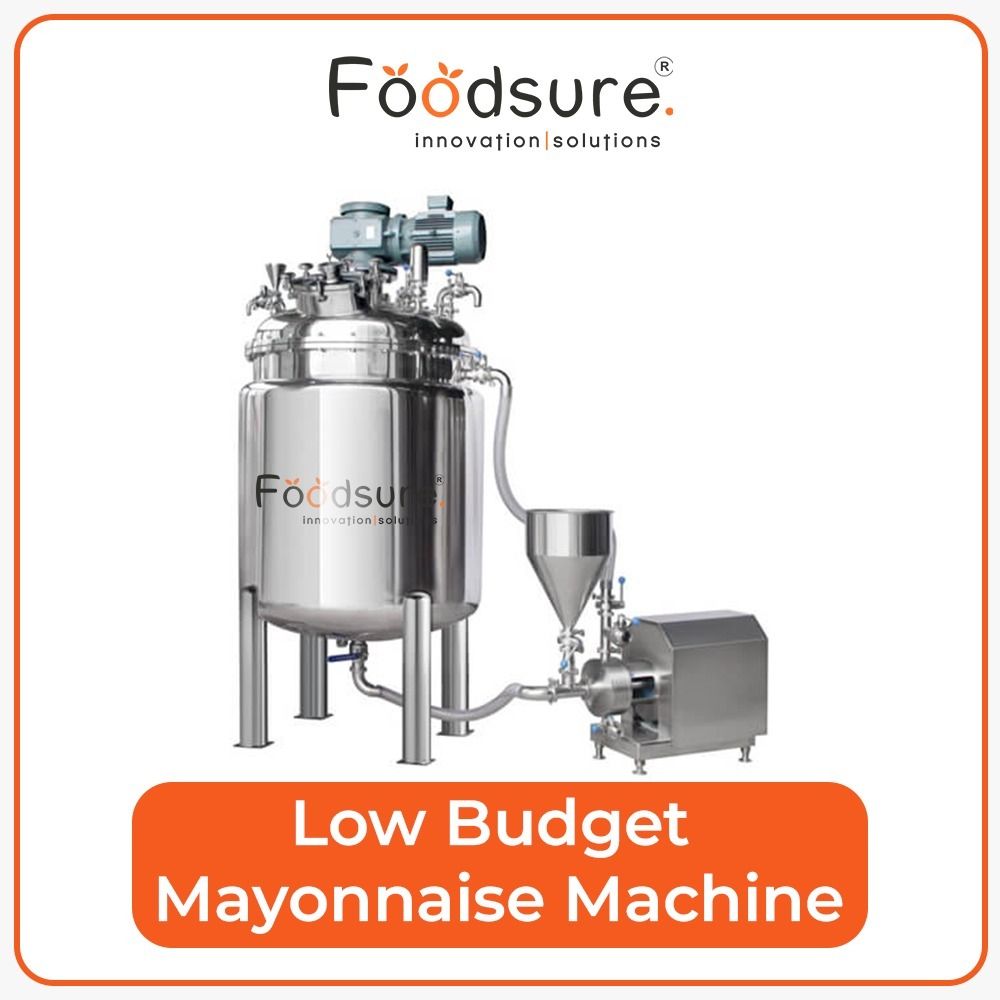

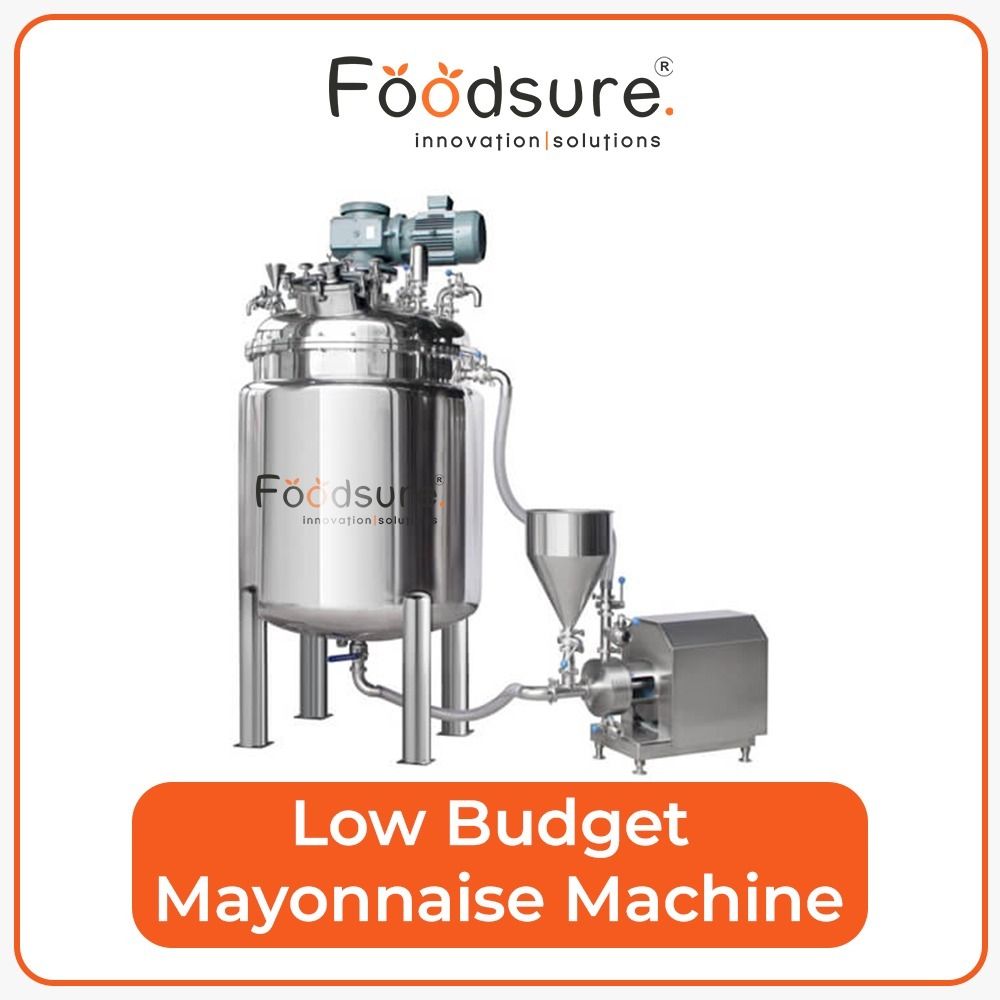

- Mixing Tank: A large tank used to mix the ingredients of the mayonnaise. It may have a motorized mixer or agitator to ensure even mixing.

- Emulsifying Machine: A specialized machine used to emulsify the mixture of oil, vinegar or lemon juice, and other ingredients into a smooth and creamy mayonnaise.

- Homogenizer: A machine used to break down the fat particles in the mayonnaise to create a smooth and consistent texture.

- Filling Machine: A machine used to fill jars, bottles, or other containers with mayonnaise. It may be a manual or automated machine, depending on the volume of production.

- Labeling Machine: A machine used to apply labels to the filled jars or bottles of mayonnaise. Capping Machine: A machine used to apply caps or lids to the filled jars or bottles of mayonnaise.

- Packaging Machine: A machine used to package the filled and labeled jars or bottles of mayonnaise into boxes or cases for shipment.

Overall, the use of these machines helps to streamline the mayonnaise production process, improve efficiency, and maintain consistency in the quality of the final product.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+