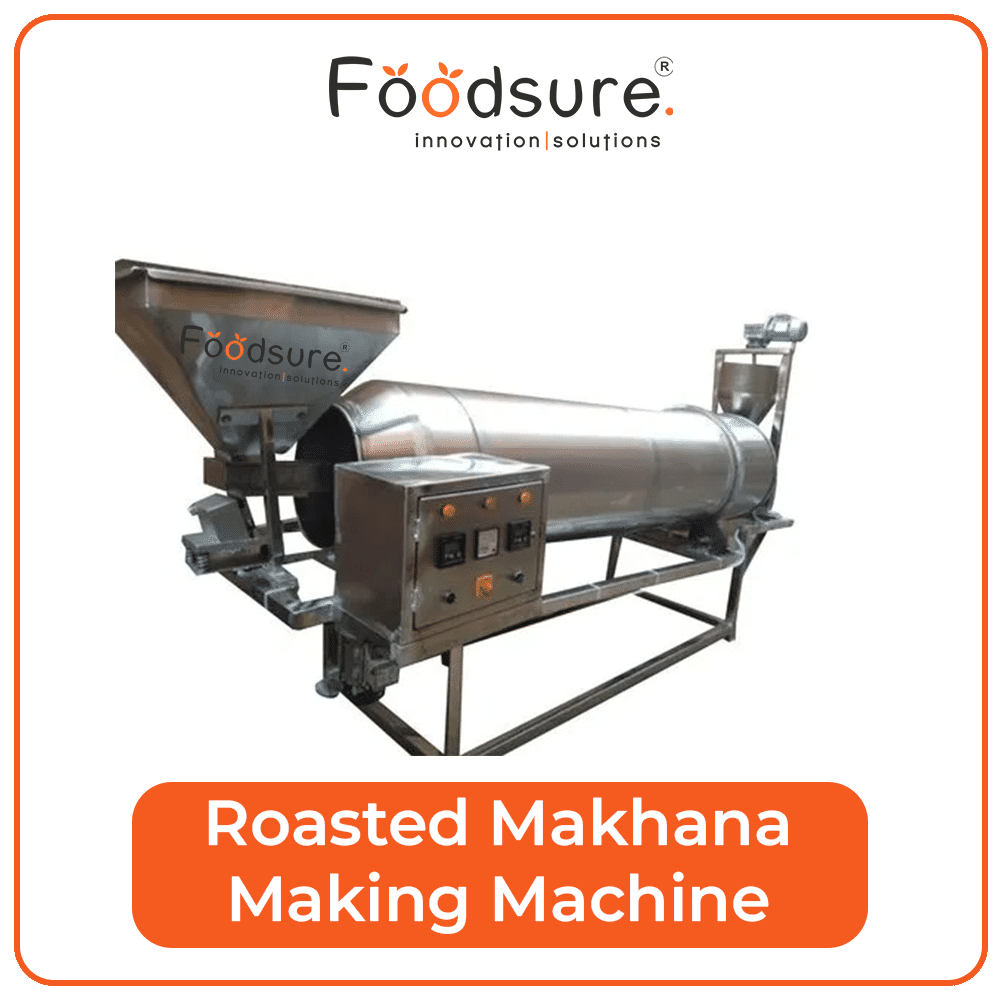

Makhana Machine

Product Details:

- Product Type Roasted Makhana

- General Use Industrial and Commercial

- Material Stainless Steel

- Capacity upto 100 kg Kg/hr

- Automatic Yes

- Control System PLC Control

- Voltage 420 Volt (v)

- Click to View more

Makhana Machine Price And Quantity

- 1 Pieces

- 1000000.0 INR/Unit

Makhana Machine Product Specifications

- 20 Watt (w)

- ECO Friendly

- Stainless Steel

- PLC Control

- upto 100 kg Kg/hr

- Roasted Makhana

- 1 Year

- Yes

- 420 Volt (v)

- Industrial and Commercial

Makhana Machine Trade Information

- New Delhi

- Paypal Cash Against Delivery (CAD) Cash in Advance (CID) Cheque

- 10 Pieces Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging & Shrink Wrapping

- Western Europe Africa Asia Australia Central America North America Eastern Europe South America Middle East

- All India

- ISO 9001:2018

Product Description

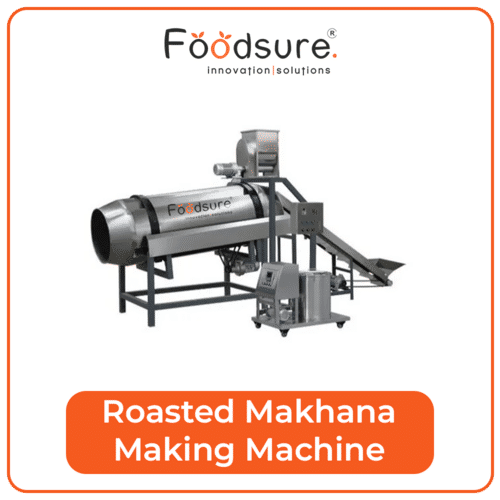

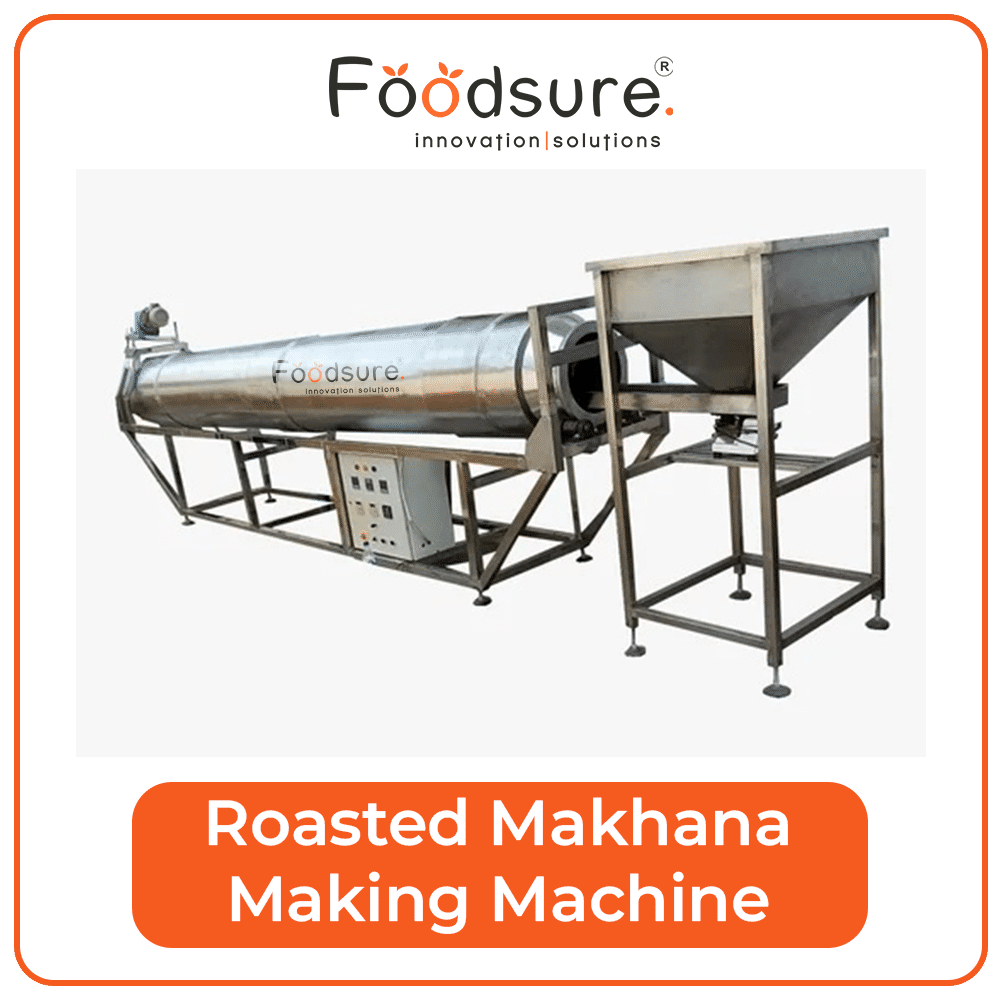

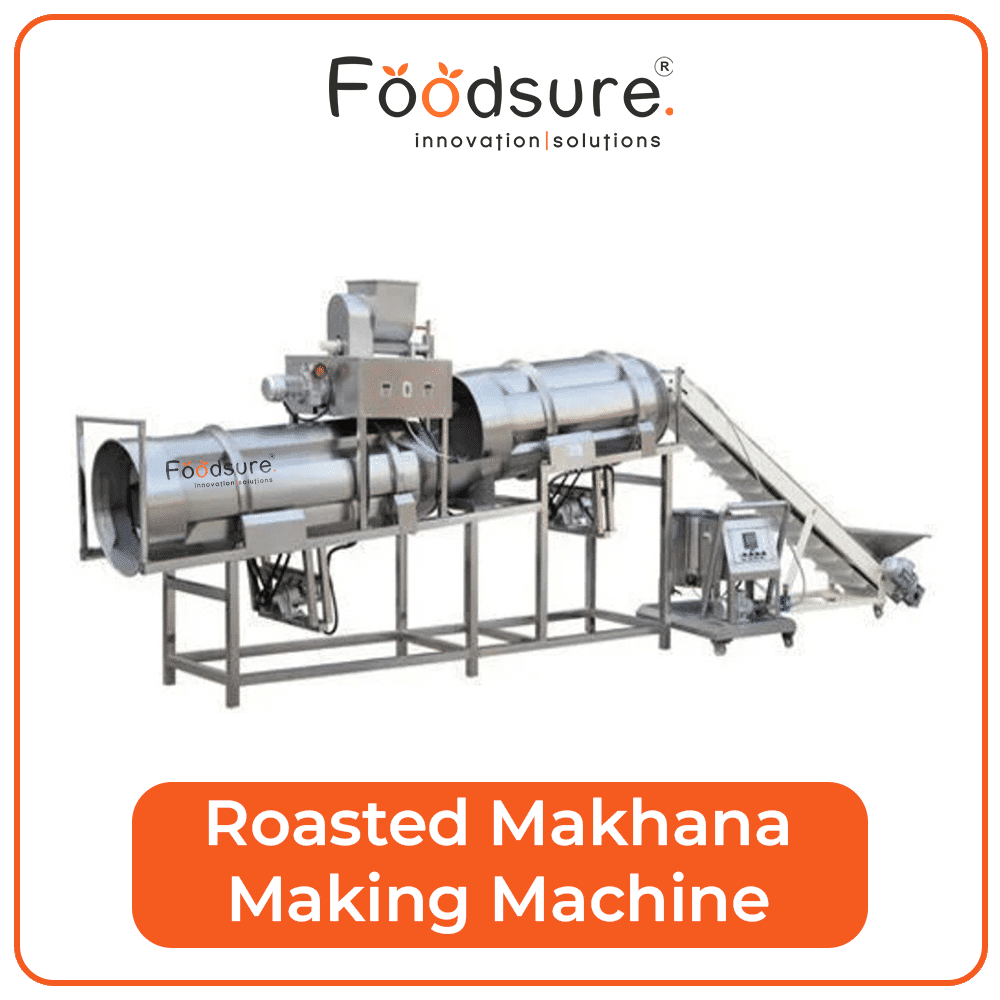

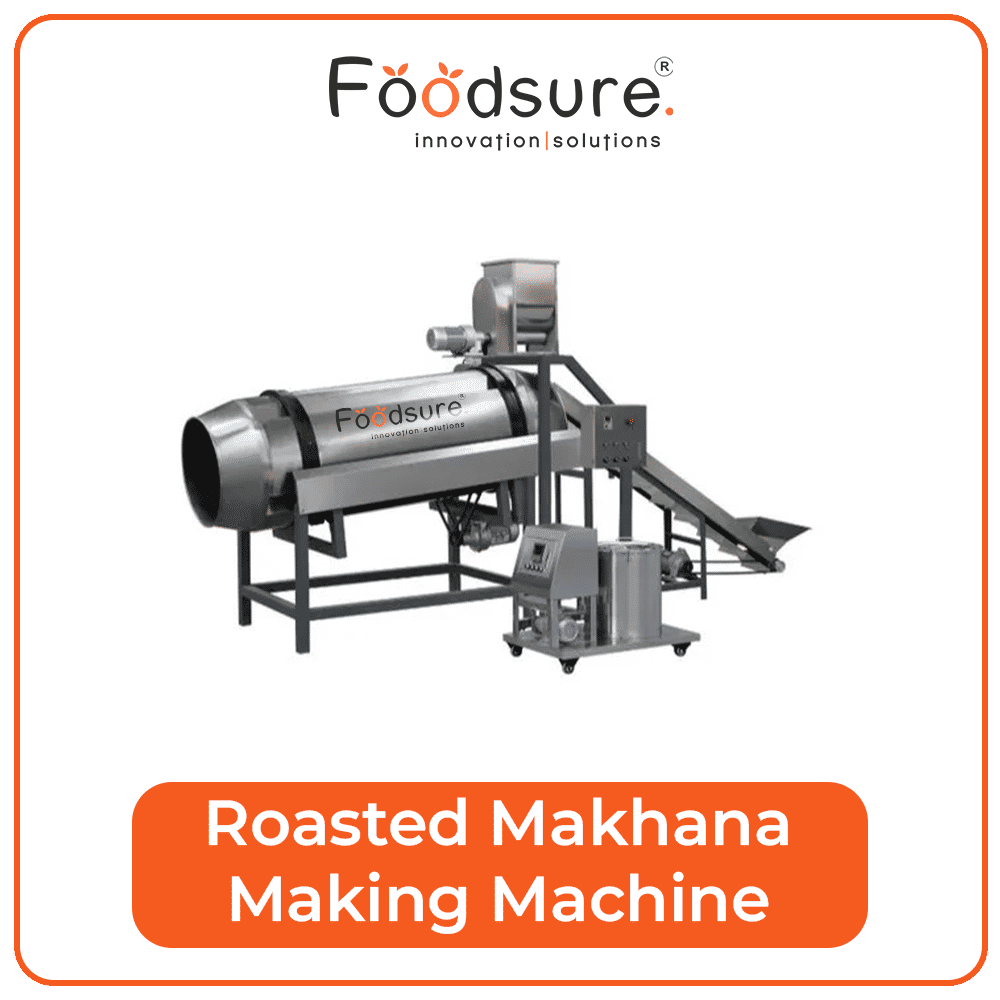

The Makhana machine is designed to streamline the processing of foxnuts with advanced technology, ensuring high efficiency and quality output. This fully automatic Makhana machine includes a grader, roaster, seasoning coater, seasoning kettle for masala preparation, conveyor, Zed elevator, and packaging machine. Each component of the Makhana machine is made of 100% SS 304 stainless steel, ensuring durability and food-grade safety standards.

With the Makhana machine, the grading system ensures precise sorting, while the roaster reduces moisture to optimal levels. The seasoning coater allows for even distribution of flavoring, and the packaging machine completes the process with airtight sealing. The Makhana machine operates seamlessly, allowing for continuous production, which makes it an ideal choice for large-scale manufacturers. Investing in a Makhana machine ensures that your production line is efficient and produces consistently high-quality products.

SS 304 stainless steel, this machine ensures food safety, durability, and high efficiency.

Grader: The process begins with the grading machine, which sorts makhana by size and quality, ensuring uniformity in the final product.

Roaster: Next, the makhana is transferred to the roaster, which evenly roasts them at controlled temperatures for optimal crunch and texture.

Conveyor: A covered conveyor system efficiently moves the roasted makhana to the next stage, preventing contamination.

Seasoning Coater: The seasoned makhana is coated uniformly in the seasoning coater, ensuring even flavor distribution.

Seasoning Kettle (Masala Preparation): The seasoning mixture is prepared in a single slurry kettle, maintaining the correct consistency for flavor coating.

Zed Elevator: The Zed elevator transfers products vertically to different processing levels without manual handling.

Packaging Machine: Finally, the packaging machine seals the flavored makhana in nitrogen-flushed pouches, ensuring long shelf life and freshness.

Equipment for Makhana Production

At Foodsure, we provide a complete range of makhana machines and Makhana processing equipment to complement our roasted makhana-making machine. These include:

Makhana Grader Machine

Makhana Roaster Machine

Makhana Flavoring Machine

Makhana Packaging Machine

Makhana Production Machine

Flavored Makhana Processing Line

Our lineup of roasted makhana machines ensures that every aspect of your production process is covered, from roasting to packaging, so you can focus on growing your business.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+