Welcome to Foodsure!

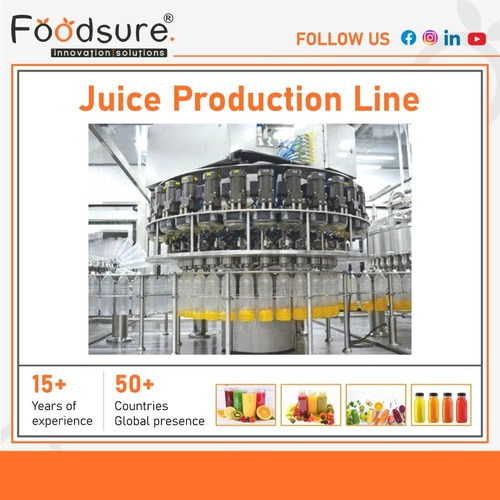

Juice Production Line

6000000.00 INR/Unit

Product Details:

X

Juice Production Line Price And Quantity

- 1 Unit

- 6000000.00 INR/Unit

Juice Production Line Trade Information

- New Delhi

- Paypal Cash Against Delivery (CAD) Cash on Delivery (COD) Cash Advance (CA) Cash in Advance (CID) Cheque

- 10 Unit Per Month

- 30 Days

- Free samples are available

- Wooden Packaging, Bubble Wrap or as per the customers

- All India

- ISO9001:2015

Product Description

A juice production line is a sophisticated assembly of machinery and equipment designed to efficiently process various fruits and vegetables into juice. Heres a comprehensive description of a typical juice production line:

- Selection and Harvesting of Raw Materials: The process begins with the careful selection and harvesting of raw fruits and vegetables. High-quality, ripe, and fresh produce is essential for producing the best juices.

- Cleaning and Sanitizing: Once harvested, the produce undergoes thorough cleaning to remove dirt, pesticides, and other contaminants. Sanitization follows to eliminate pathogens and ensure the safety of the juice.

- Juice Extraction: The clean produce is then passed through juice extraction equipment. This can involve mechanical pressing or enzymatic methods to separate the juice from the pulp while retaining the flavors and nutrients.

- Filtration and Clarification: The extracted juice is filtered to remove solids and clarified to ensure a smooth texture. This step also helps in achieving a clear appearance of the juice.

- Blending: Different juices may be blended to achieve the desired flavor profile. This step can also include the addition of vitamins, minerals, or other supplements to enrich the juice.

-

- Degassing and Deoiling: Juices are degassed to remove excess air, which can affect the taste and shelf life. Citrus juices may also undergo deoiling to remove oil from the peel.

- Homogenization: Homogenization is applied to break down particles and create a uniform juice consistency, improving the mouthfeel and stability of the juice.

- Pasteurization: To ensure the juice is safe for consumption, it is pasteurized to kill any remaining microorganisms. This step also extends the shelf life of the product.

- Filling and Packaging: The juice is then filled into containers, which can range from sterile bags to glass or PET bottles. The packaging process is conducted in a sterile environment to prevent contamination.

- Cooling and Storage: After packaging, the juice is cooled to an appropriate temperature for storage and distribution.

- Quality Control: Throughout the production line, quality control measures are in place to ensure the juice meets industry standards and regulations.

Enter Buying Requirement Details

Other Products in 'Processing Machines' category

Back to top