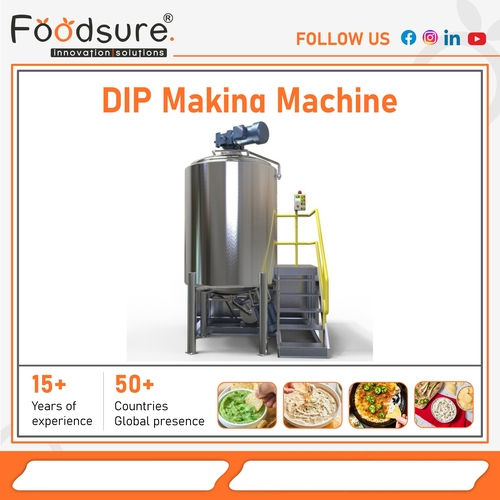

Dips and Dressing Making Machine

Product Details:

- Product Type Dips and Dressing

- General Use Industrial and Commercial

- Capacity Upto 3000 Kg/hr

- Weight (kg) 1000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Control System Manual

- Click to View more

Dips and Dressing Making Machine Price And Quantity

- 500000.00 INR/Unit

- 1 Unit

Dips and Dressing Making Machine Product Specifications

- 20 Watt (w)

- Manual

- Yes

- Dips and Dressing

- 1 Year

- Upto 3000 Kg/hr

- ECO Friendly, Low Noice, Lower Energy Consumption, Compact Structure, High Efficiency

- Yes

- Table Top

- Industrial and Commercial

- 1000 Kilograms (kg)

- 420 Watt (w)

Dips and Dressing Making Machine Trade Information

- New Delhi

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Pouch Packaging, Pet Bottle Packaging

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- ISO9001:2015

Product Description

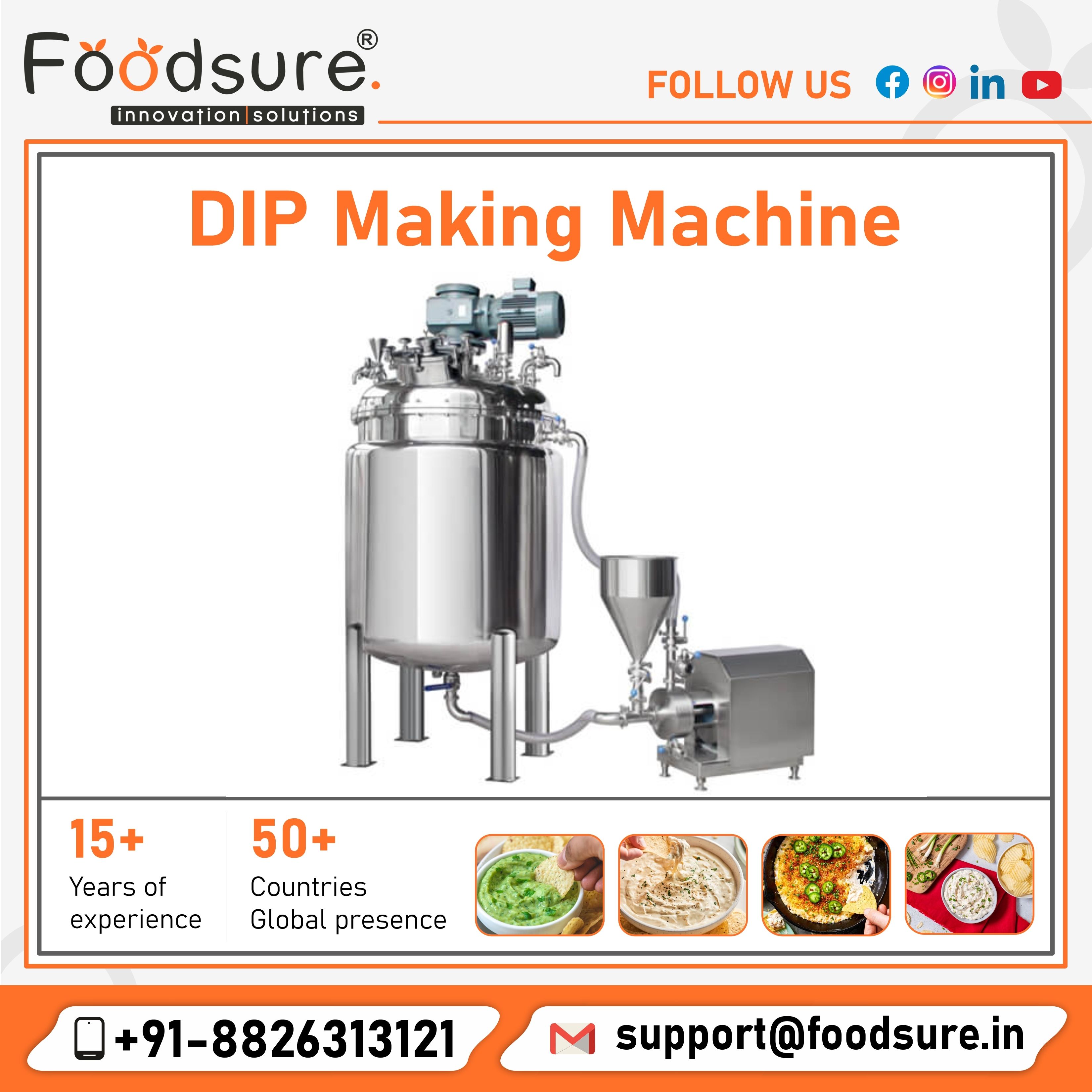

The Dips & Dressing Making Machine is a specialized piece of equipment designed to efficiently produce a variety of dips and dressings with consistent quality and texture. This machine is specifically engineered to handle the mixing, blending, and emulsifying processes involved in creating delicious and smooth dips and dressings.

The machine features a robust construction with stainless steel components, ensuring durability, hygiene, and easy cleaning. It is equipped with a powerful motor and precise controls to achieve uniform blending and mixing results. The mixing chamber is designed to accommodate various batch sizes, allowing for flexibility in production.

The Dips & Dressing Making Machine incorporates advanced technology to ensure efficient emulsification and blending of ingredients. It effectively combines various components such as herbs, spices, oils, vinegars, and other flavorings to create well-incorporated and flavorful dips and dressings.

The machine may include additional features such as temperature control, allowing for precise heating or cooling during the mixing process. This ensures that the dips and dressings reach the desired consistency and maintain their freshness.

Furthermore, the Dips & Dressing Making Machine is designed with ease of use and maintenance in mind. It is equipped with user-friendly interfaces and accessible parts for convenient operation and cleaning. This promotes efficient production and helps maintain high food safety standards.

By utilizing the Dips & Dressing Making Machine, food manufacturers can streamline their production processes, improve product consistency, and enhance efficiency. It enables them to meet the demand for a wide range of dips and dressings while ensuring reliable and hygienic manufacturing practices. Whether used in commercial kitchens, food processing plants, or industrial settings, this machine is a valuable asset for producing delicious and high-quality dips and dressings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+