Welcome to Foodsure!

Oats Plant Setup

1000000.00 INR/Unit

Product Details:

- Product Type Food Processing Machine

- General Use Commercial, Industrial

- Material Stainless Steel

- Computerized Yes

- Automatic Yes

- Control System Manual

- Voltage 440 V Volt (v)

- Click to View more

X

Oats Plant Setup Price And Quantity

- 1 Unit

- 1000000.00 INR/Unit

Oats Plant Setup Product Specifications

- Yes

- 440 V Volt (v)

- Food Processing Machine

- Commercial, Industrial

- Stainless Steel

- Manual

- Yes

Oats Plant Setup Trade Information

- New Delhi

- Paypal, Cash Against Delivery (CAD), Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- 10 Unit Per Month

- 30 Days

- Yes

- Free samples are available

- Wooden Packaging, Bubble Wrap Packaging

- All India

- ISO9001:2015

Product Description

Setting up an oats processing plant involves several key steps, from sourcing raw materials to packaging the final product. Here a general overview of the process:

- Market Research and Planning: Conduct market research to understand consumer demand, market trends, and potential competitors in the oats industry. Develop a business plan outlining your goals, target market segments, production capacity, and financial projections.

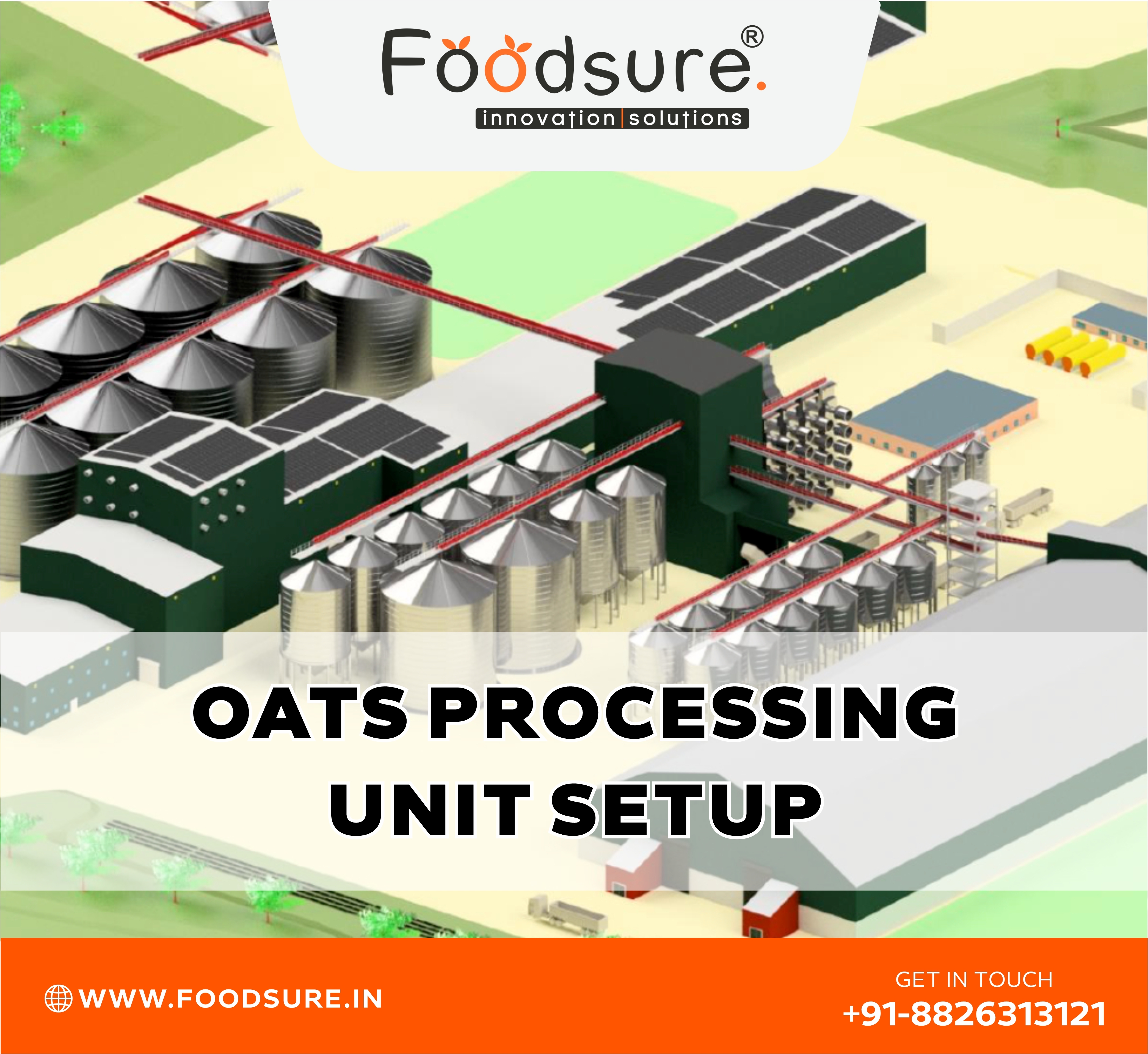

- Location and Facility Selection:Choose a suitable location for your oats processing plant, considering factors such as proximity to oat farms, transportation logistics, and access to utilities like water and electricity.Design or acquire a facility that meets regulatory requirements and provides sufficient space for processing, storage, packaging, and administrative functions.

- Raw Material Sourcing:Procure high-quality oats from reputable suppliers, including oat growers, cooperatives, or grain brokers.Establish relationships with oat suppliers to ensure a consistent and reliable supply of raw materials throughout the year.

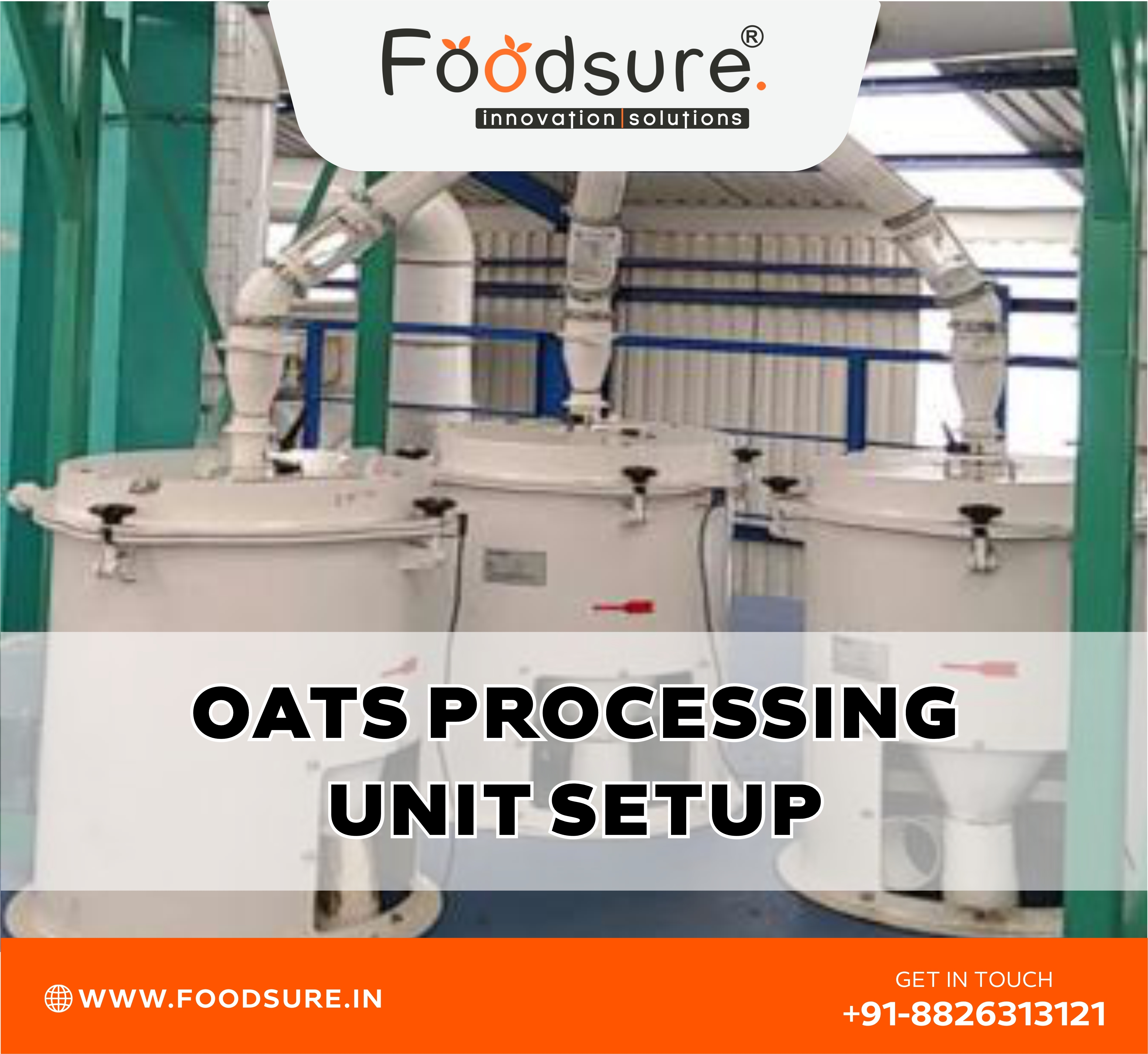

- Processing Equipment:Invest in specialized processing equipment for cleaning, hulling, dehulling, milling, and packaging oats.

- Ensure that the equipment is capable of handling different oat varieties and processing methods while meeting food safety and quality standards.

- Cleaning and Hulling:Clean the raw oats to remove impurities such as dirt, stones, and other foreign materials.

- Hull or dehull the oats to remove the outer husk while preserving the oat groat inside.

- Milling and Processing:Mill the dehulled oats into various oat products, including oat flakes, oat flour, oat bran, and oatmeal.

- Customize the milling process based on product specifications, such as texture, particle size, and moisture content.

- Packaging and Labeling:Select appropriate packaging materials, such as bags, boxes, or bulk containers, to preserve the freshness and quality of oats.Design labels that comply with regulatory requirements and provide essential information to consumers, such as nutritional content, cooking instructions, and allergen warnings.

- Quality Control and Assurance:Implement quality control measures at each stage of the processing operation to ensure product consistency, purity, and safety.

- Conduct regular inspections, tests, and audits to verify compliance with food safety standards and regulatory requirements.

- Distribution and Logistics:Establish distribution channels to reach wholesalers, retailers, food manufacturers, and foodservice providers.Coordinate transportation logistics to deliver oats to customers efficiently while minimizing costs and environmental impact.

- Marketing and Sales:Develop marketing strategies to promote your oats brand, including advertising, packaging design, and participation in trade shows or industry events.Educate consumers about the nutritional benefits of oats and create innovative oat-based recipes to inspire usage and drive demand.

- Continuous Improvement:Monitor customer feedback, market trends, and industry developments to identify opportunities for product innovation and process optimization.

- nvest in research and development to explore new oat products, improve processing efficiency, and enhance sustainability practices.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Processing Machines' category

Back to top