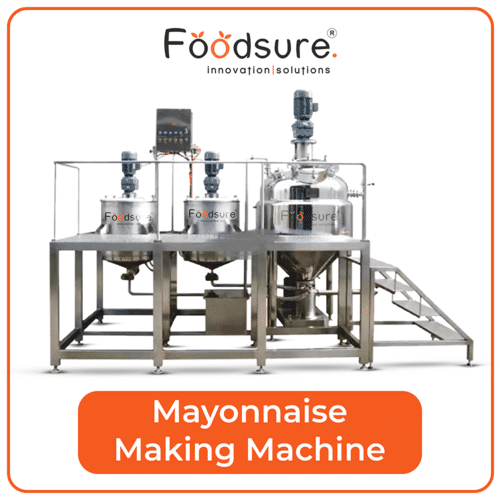

Mayonnaise Making Machine in Indore

Product Details:

- Product Type Food Processing Machine

- General Use Commercial, Industrial

- Material Stainless Steel

- Computerized Yes

- Automatic Yes

- Control System Manual

- Voltage 440 V Volt (v)

- Click to View more

Mayonnaise Making Machine in Indore Price And Quantity

- 1 Unit

- 1500000 INR/Unit

Mayonnaise Making Machine in Indore Product Specifications

- Commercial, Industrial

- Yes

- Food Processing Machine

- 440 V Volt (v)

- Manual

- Yes

- Stainless Steel

Product Description

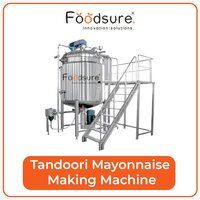

Mayonnaise making machine in Indore

Foodsure offers the latest mayonnaise plant solution designs to ease production and make sure to provide the highest quality results to its clients. Our mayonnaise plants provide them with unique and original machinery and technology to easily process and package mayonnaise products. Processes include, from emulsification to pasteurization and packaging, our plants handle every stage of the production process with clarity and stability.

Food safety is our priority and we strictly follow quality control rates to make sure that our mayonnaise products match the highest industry standards. Our mayonnaise plants are all-round and made to different production capacities and product variations. Whether you're producing traditional mayonnaise, flavoured variants, or speciality formulations, our plants can be created to suit your major requirements.

With Foodsure's Mayonnaise plant solutions, you can expect:

-

Systematic Production:Our plants are made for perfect efficiency, allowing you to increase productivity and minimize the struggle in production work.

-

Quality Standards:We maintain quality control rates throughout production to make sure that every step matches your quality standards.

-

Flexibility:Our plants are flexible to make changes in production requirements, allowing you to scale up or down as needed.

-

Current technology trends:We use the latest technology and innovation to set up the plant's performance and improve product quality.

-

Team of Experts:Our team of skilled professionals provides complete support, from the beginning of plant design to installation, training, and other maintenance.

No matter, whether you are a small-scale producer or a large manufacturing company, Foodsure's mayonnaise plant solutions provide an accurate and less expensive solution for your production needs.

Join hands with us, achieve your targets, and take your mayonnaise production to a high level with ease in effort.

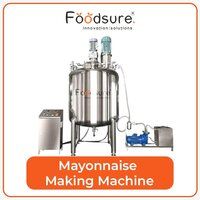

A mayonnaise machine is a creative equipment used for mixing, emulsifying & packaging large quantities of mayonnaise. These machines are mainly used in food production processes like for factories or commercial units.

Fully functional machines are made specifically for mixing & emulsifying ingredients in mayonnaise, while others are made for mixing & packaging. The most common mixing method is to mix oil, vinegar, lemon juice & other ingredients in a large bowl or container.

Some machines that can be used in the mayonnaise process are described below:

-

High-shear mixers:High-shear mixers are the central part of the mayonnaise production process. These mixers are made to easily blend the oil and egg yolk mixture, checking the perfect mixture.

-

Emulsifier Machines:Equipment Emulsifier Homogenizers are important in achieving the thickness and texture of mayonnaise.

-

Filling Equipment:Once the mayonnaise is ready, it needs to be packaged for distribution. After this purpose, packaging and bottling have a major role to play.

-

Labeling Machine:This machine is used to attach labels to containers or bottles.

-

Capping Machine:It is a machine used for closing. Close the jar or bottle filled with mayonnaise.

-

Packing Machine:A machine used to pack containers and fill cans or bottles of mayonnaise into cartons or boxes for shipping.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+